Features:

Features:

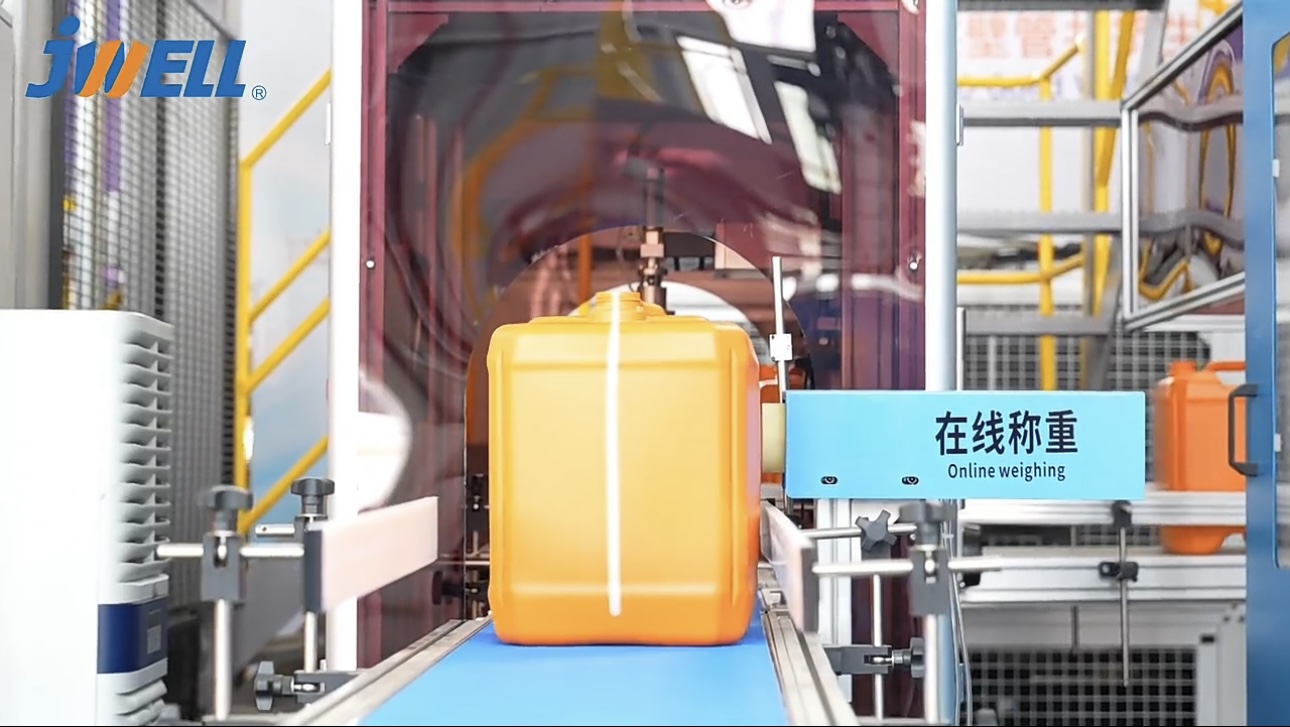

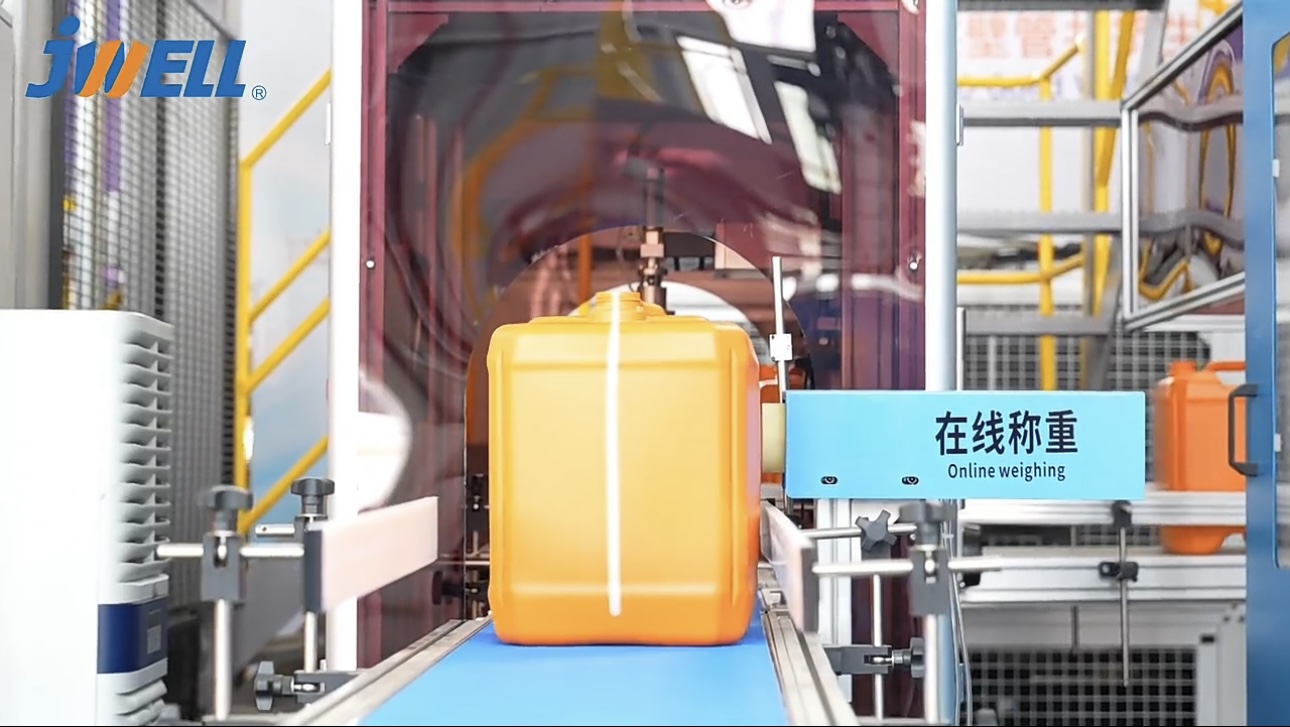

1.JWZ-BM30Plus is suitable for producing 20-30L jerrycan ,adopting three-layer continuous diehead with view strip line and U-shape mould-locking ,down-blowing structure.It is equipped with automatic loader, on-line auto de-flashing, once strong cooling , thrice auxiliary fixing, on-line leak testing, reserved on-line weighing and spraying workstation, conveying etc.The unmanned intelligent blow molding machine will greatly reduce the labor intensity and improve the efficiency.

2.Adopt B&R automation control system, it supports multi-task time-sharing operation with high degree of automation; advanced man-machine interface replaces the conventional panel control system, and the new generation of programmable computer controllers represents a new level of industrial control, which integrates the functions of PLC and industrial computers, and the operating procedures (parameters) can be stored.Centralised display of the operating status of the machine, open structure and bus interface。

3. The mould frame adopts JW 5th generation two-platen U-type structure, and the mould clamping is driven by servo swing arm rotation, with small friction resistance, good motion characteristics and high clamping accuracy.In order to be stable and cost-effective, the sub-mould clamping is equipped with a power pack.Compared with the conventional hydraulic machine, full electric blow molding machine can significantly increase the output, reduce energy consumption and pollution.The frame has the features of clamping evenly, large clamping force, large mould capacity and more convenient disassembling and assembling for the mould.

4.Adopt continuous three-layer die head with view strip line, in the case of ensuring the stretching and compactness of the parison, it is relatively better for the colour change, the delamination control and the product surface .The recycled material is used in the middle layer of the product, and the inner and outer layers are covered with new material, the appearance of the product is the same as that of brand-new material, and the hardness and performance are improved.

5. This unit places the conveyor for semi-finished products in the de-flashing station, turns them over to the cooling system after deflashing , and uses high and low-pressure circulating air cooling .Use continuous low-temperature dry air circulating cooling shorten the cooling time.Then auxiliary shaping + online leak testing and weighing.

6. The power of the whole machine is driven by servo motors, with a total of 5 sets of servo.

The servo downward moving parison robot replaces the function of shooting of the conventional accumulating type blow molding machine and the platen moving of continuous one. When die head lifts, the robot puts the parison into the mould and parison inflation.Servo take-out robot moves the moulded products to the de-flashing system , the overall action has low inertias loads and high controllability,more energy-saving and efficient

Independent opening and closing platen servo power.

Servo down blowing, accurately achieve micro-extraction, obtuse mouth action Servo power pack system achieves mould locking + sub-mould action.The system provides precise displacement and force by controlling the speed and torque of the motors; and the action response is faster, more explosive and more efficient.

This model is suitable for the production of 20/30 litre jerrycan , which gives customers greater advantages and competitiveness in the market.It can cater to the market demand, create economic benefits for customers, and has a wide market prospect.

JWZ-BM30Plus JWZ-BM 30Plus blow-moulding machine |

Model | Unit | JWZ-BM 30Plus |

Max product volume | L | 30 |

Dry cycle | pc/h | 280 |

Number of working station |

| Single |

Parison mould structure |

| Three layer continuous type with view strip line |

Max die pin diameter | MM | 240 |

Screw L/D ratio |

| 25 |

Capacity | Kg/h | 220 |

Driving motor | KW | 22KW+37KW+22KW |

Number of barrel heating zone | Zone | 4+4+4 |

Heating power of main barrel | KW | 46 |

parison shifting robot | MM | 上下行程800 |

take-out robot | MM | 进退行程800 |

Max space between platens | MM | 350-880 |

Platen size W*H | MM | 600*640 |

Clamping force | KN | 280 |

|

Air pressure | Mpa | 0.7 |

Air consumption | M3/h | 90 |

Cooling water pressure | Mpa | 0.3 |

Cooling water consumption | t/h | 8-9 |

Overall dimension L*W*H | M | 6.3*3.7*4.7 |

Total weight | ton | 18 |

Total power | KW | 150 |

Note: Information listed above are for reference only, the production line can be designed by customer’s requirements.

Workshop Display

Why Customers Choose JWELL?

Professional Expertise: years of deep experience in extrusion technology, with a thorough understanding of various industry process requirements.

Quality Certification: Equipment is CE certified, with core components from leading international brands, ensuring long-term stable operation.

Service Guarantee: Provides full life-cycle support from custom solution design and installation/commissioning to technical training and lifetime maintenance.

Get Your Custom Solution Now

Are you looking for a production partner to boost your capacity and reduce costs? Our engineering team is ready to assist you!