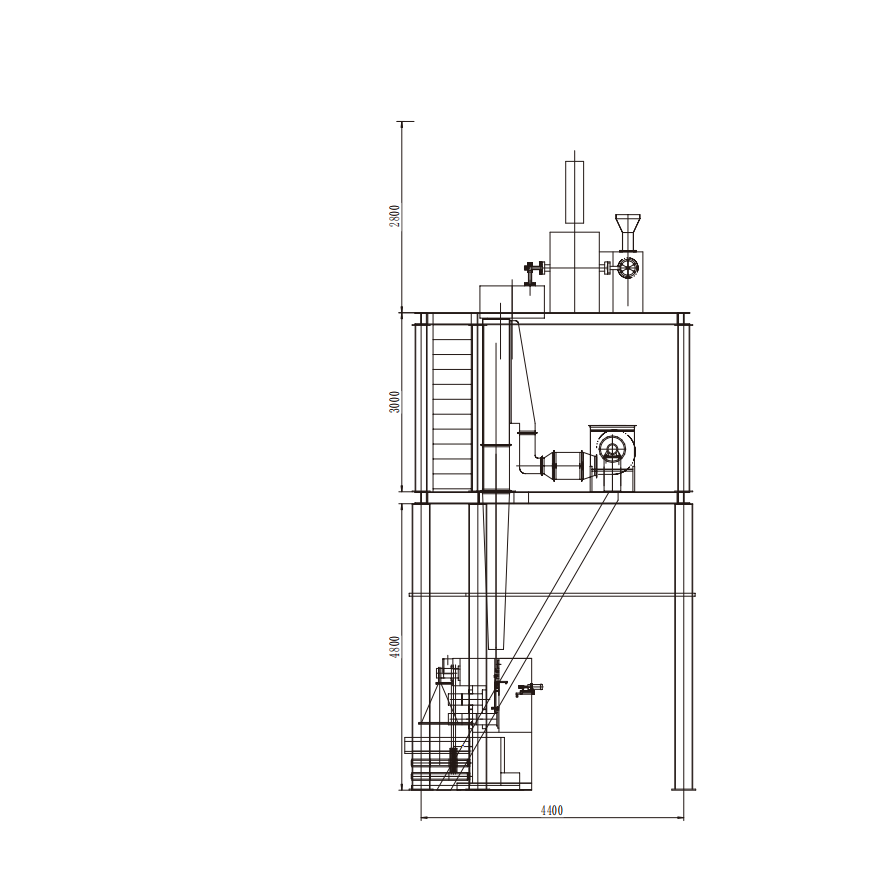

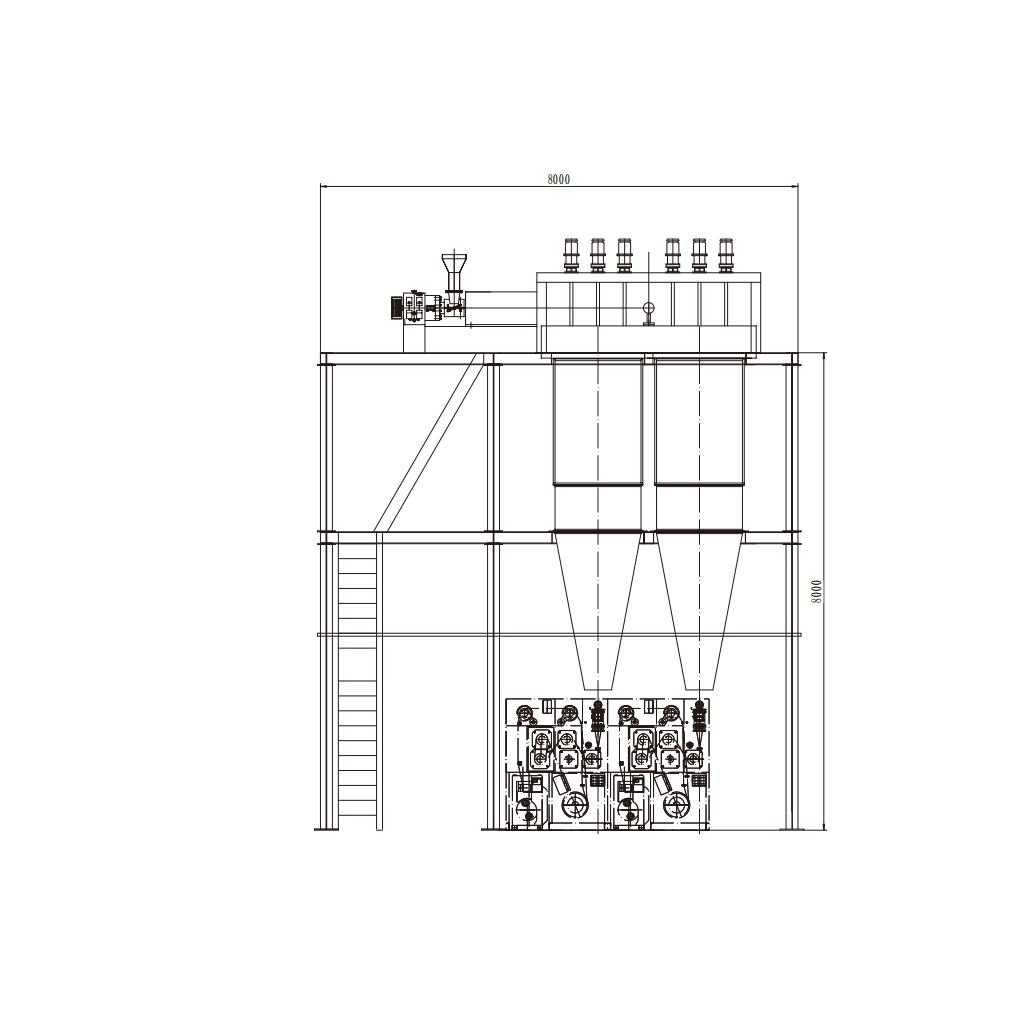

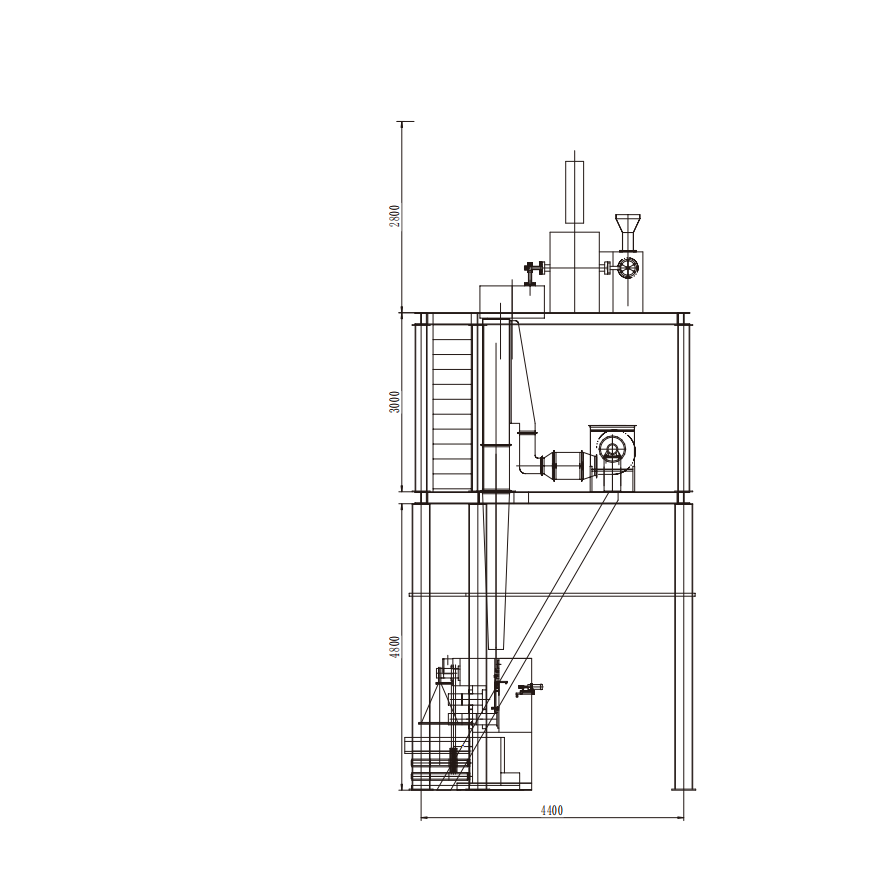

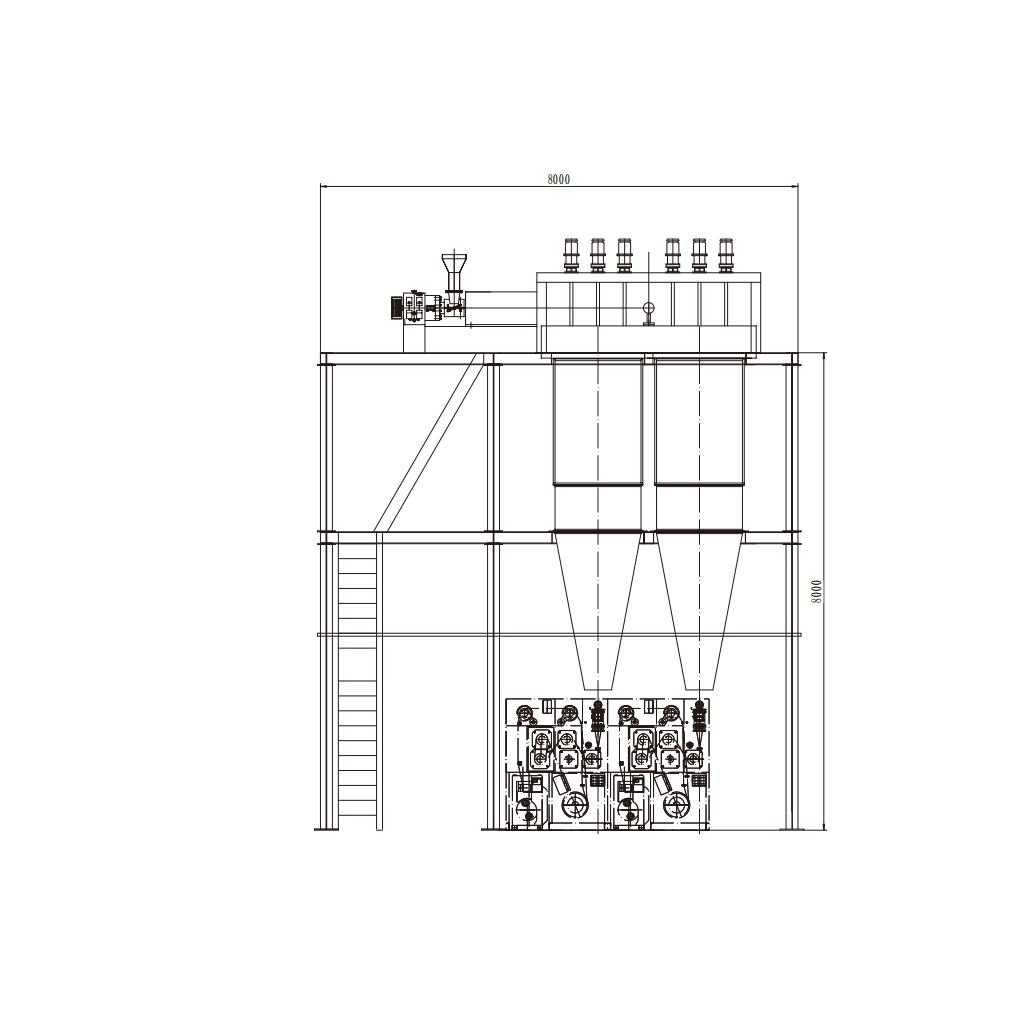

Fiber Spinning Machine

JWELL Fiber Equipment Company is a high-tech enterprise dedicated to the research and manufacturing of synthetic fiber spinning equipment.

With over 30 years of rich experience in the synthetic fiber industry, it has become a strong, well-equipped, and leading international engineering company in fiber machinery, specializing in synthetic fiber project design and equipment manufacturing.

Application Industries

Synthetic Fiber Manufacturing

Automate high-volume production of polyester, nylon, and polypropylene fibers with precision temperature control and customizable spinneret configurations.

Technical Textiles

Produce advanced fibers for automotive composites, medical textiles, and geotextiles using adaptive extrusion and winding systems.

Recycled Material Processing

Integrate eco-friendly solutions for recycled PET and bio-based polymers, reducing waste and energy consumption.

Product Advantages

Independent research, design, and production

JWELL Fiber Machinery Co.,Ltd (SUZHOU) relies on independent production and develop core components, such as extruder, spinning beam and winder, these core components applies lots of patents. Screw&barrel adopts international famous brand "Jinhailuo", and three key components of winder like traverse cam , contact roll and chuck has independently designed and developed ability.

Strict quality control

The dynamic balance process of winder three components has strict quality control, equipped with independent production manufacturing CNC equipments, assembly, and quality inspection workshop.

Customizable

JWELL has accumulated extensive successful case experience both domestically and internationally.we provide customized solutions based on customer technical processes and product requirements, while also offering comprehensive engineering solutions in all aspects.

Service Commitment

We offer lifetime after-sales service: from initial on-site factory surveys, equipment specification communication, process design and installation debugging& trainning, 24-hour after-sales emergency response, remote intelligent diagnostics and lifetime after-sales support of technical upgrade.

FAQs

Q: How does JWELL ensure machine durability?

A: Core components (screws, barrels) use dual-layer alloy steel with nitride hardening, tested for 10,000+ hours of continuous operation.

Q: Do you offer post-sale technical support?

A: Yes! JWELL provides global 24/7 remote diagnostics, on-site engineer commissioning, and operator training programs.

Q: Can existing production lines integrate JWELL machines?

A: Absolutely. Our team designs retrofittable solutions with PLC/SCADA compatibility for seamless automation upgrades.

Related Blogs

-

In the ever-evolving world of fashion, innovation is key to staying ahead of the game. One revolutionary technology that has the potential to transform clothing production is a high-speed spinning line. With its numerous advantages and impact on the fashion industry, this cutting-edge system is poisIndustry News

In the ever-evolving world of fashion, innovation is key to staying ahead of the game. One revolutionary technology that has the potential to transform clothing production is a high-speed spinning line. With its numerous advantages and impact on the fashion industry, this cutting-edge system is poisIndustry News -

In today's fast-paced fashion industry, the need for efficient and high-quality clothing production has become paramount. To meet the growing demands of consumers, manufacturers are constantly on the lookout for innovative technologies that can streamline their operations. One such technology that hIndustry News

In today's fast-paced fashion industry, the need for efficient and high-quality clothing production has become paramount. To meet the growing demands of consumers, manufacturers are constantly on the lookout for innovative technologies that can streamline their operations. One such technology that hIndustry News -

Introduction to Bottle Flake Spinning Equipment Welcome to the world of eco-friendly PET production! In a time where sustainability is more crucial than ever, industries are constantly seeking innovative solutions to reduce their environmental impact. One such solution that has garnered attention inIndustry News

Introduction to Bottle Flake Spinning Equipment Welcome to the world of eco-friendly PET production! In a time where sustainability is more crucial than ever, industries are constantly seeking innovative solutions to reduce their environmental impact. One such solution that has garnered attention inIndustry News

Keep in touch with us

30+ years of R&D in extrusion technology

300+ engineers and 1,000+ production lines deployed globally

ISO 9001 certified with 100+ patented innovations

Mob:+86-13601907989

E-mail:saldf@jwell.cn