In plastic extrusion equipment, the rollers are crucial molding and cooling components, directly affecting the surface roughness, transparency, thickness uniformity, and dimensional stability of the product. However, in actual production, many customers easily overlook a critical detail—the choice of roller material should differ depending on the raw material.

Today, let's talk about which roller materials are suitable for common raw materials such as PET, PC, PMMA, ABS, EVA, PP/PS, and PE, and why we should choose them this way.

1.Why is the selection of roller materials important?

The rollers need to withstand high temperatures, pressure, and continuous operation, while also being in direct contact with molten plastic. Improper material selection can easily lead to the following problems:

-The surface is not wear-resistant, which affects the surface roughness of the product;

-Low heat transfer efficiency and uneven temperature control;

-Material fatigue leads to cracking, deformation, indentation, and pitting on the roller surface;

-Material corrosion leads to oxidation and rust on the roller surface;

-High maintenance costs.

Therefore, different plastic materials must be matched with appropriate roller materials to ensure stable equipment operation and high-quality product output.

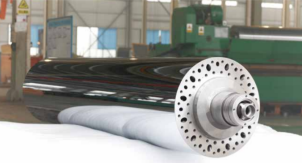

(The image shows cracks appearing on the roller)

2.What are the advantages of Jwell rollers?

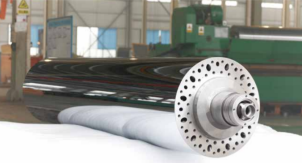

As a professional manufacturer of plastic extrusion equipment and accessories, we focus on the research and development and manufacturing of core components such as rollers, moulds, and screw barrels. Our products are widely used in extrusion and stretching production lines for sheets, plates, and films, and have the following characteristics:

-Selected high-quality roller materials: including 9Cr2Mo, 42CrMo, Q345, 45# steel, stainless steel, aluminum alloy, copper, etc;

-Jwell offers a variety of surface treatments: hard chrome plating, nickel plating, electroless nickel plating, spray coating, matte finish, and high-precision polishing;

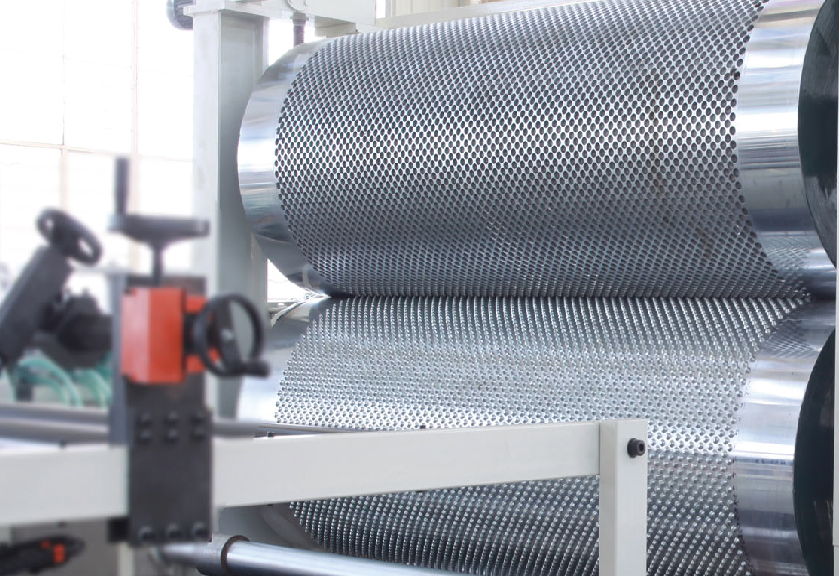

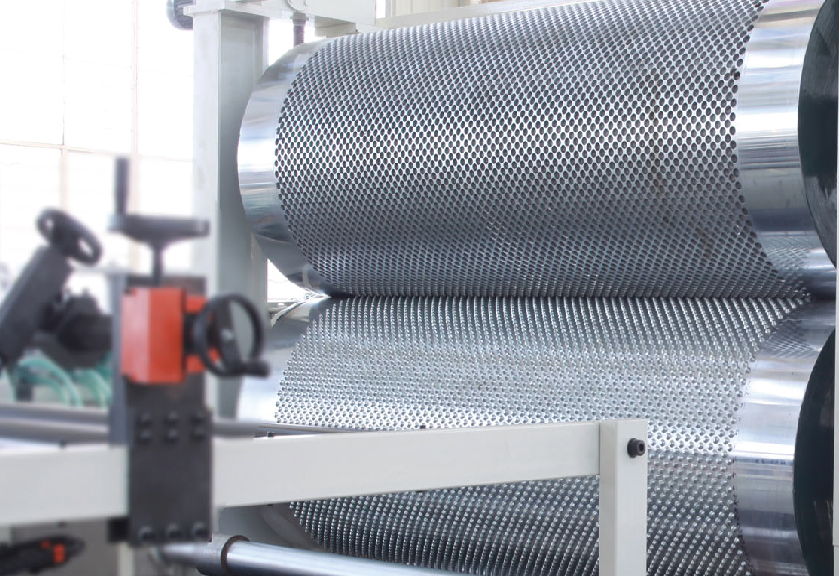

-Various types: super mirror roller, thin-wall efficient roller, embossing roller, casting roller, chill roller, hot mill roller, casting film roller, electromagnetic heating roller;

-The precise manufacturing process and excellent dynamic balance ensure long-term stable operation;

-Jwell rollers can provide customized services.

3.Why differentiate between roller materials when the raw materials are different?

Different plastics vary in processing temperature, flowability, adhesion, and corrosivity. Furthermore, the hardness of the finished products after cooling differs significantly, placing different demands on the heat conduction, surface hardness, and wear resistance of the rollers.

Choosing the wrong material may lead to:

-Poor cooling efficiency, resulting in uneven product thickness;

-The surface is easily worn, affecting surface roughness;

-Corrosion or fatigue cracking reduces service life;

-Frequent replacement or repair increases production costs.

4.Comparison of common roll materials: 42CrMo vs 45# steel

| Index | 42CrMo | 45# steel |

| Tensile Strength | ≥1080MPa | ≥600MPa |

| Yield Strength | ≥930MPa | ≥355MPa |

| Abrasion Resistance | 优

| 良 |

| Heat Treatment Performance | 62HRC | 58HRC |

| Processing Difficulty | 高 | 正常 |

5.Common plastic raw material and roller material matching table

| Raw Material Type | Common Product | Recommended Roller Materials | Recommendation |

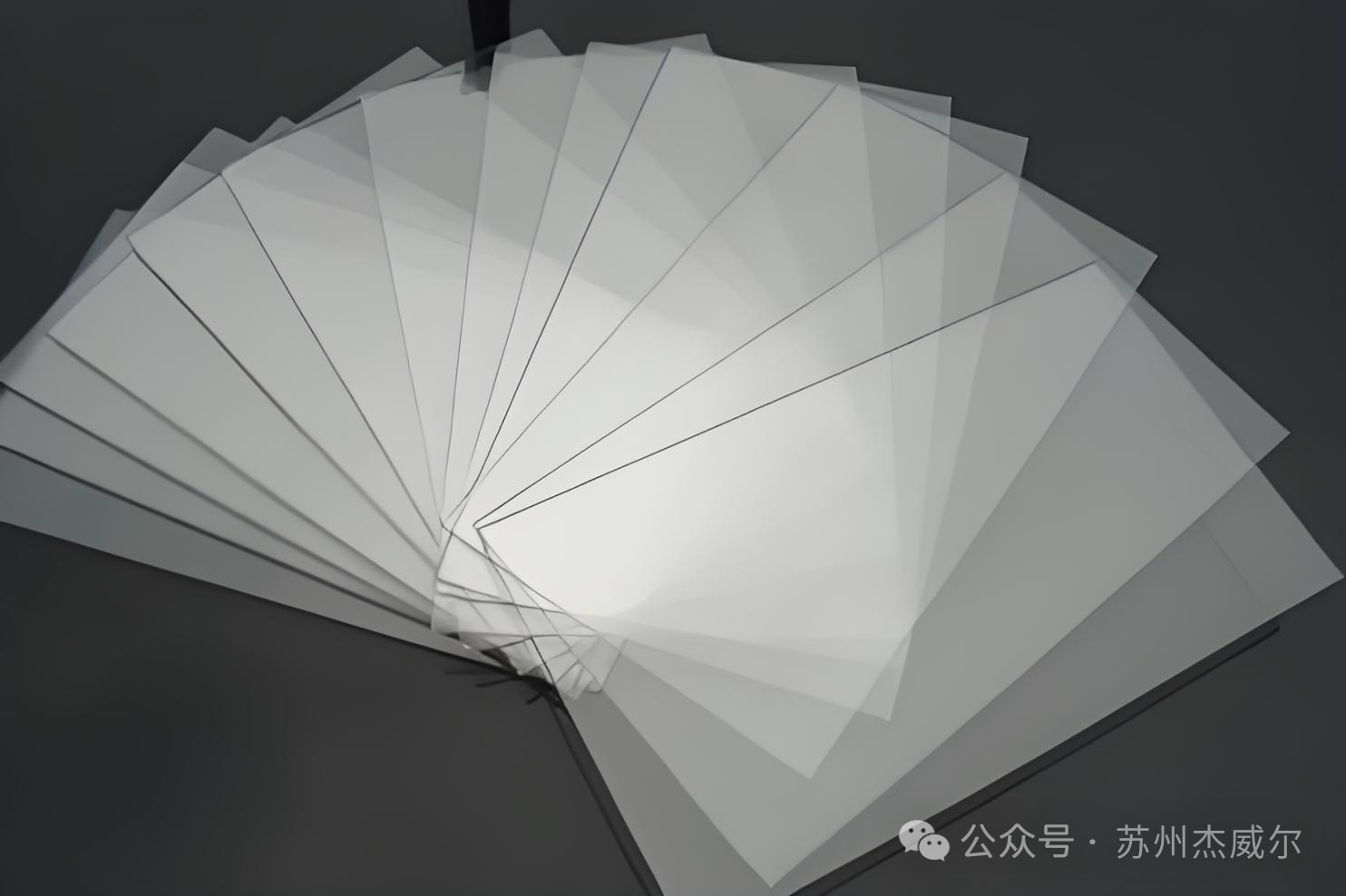

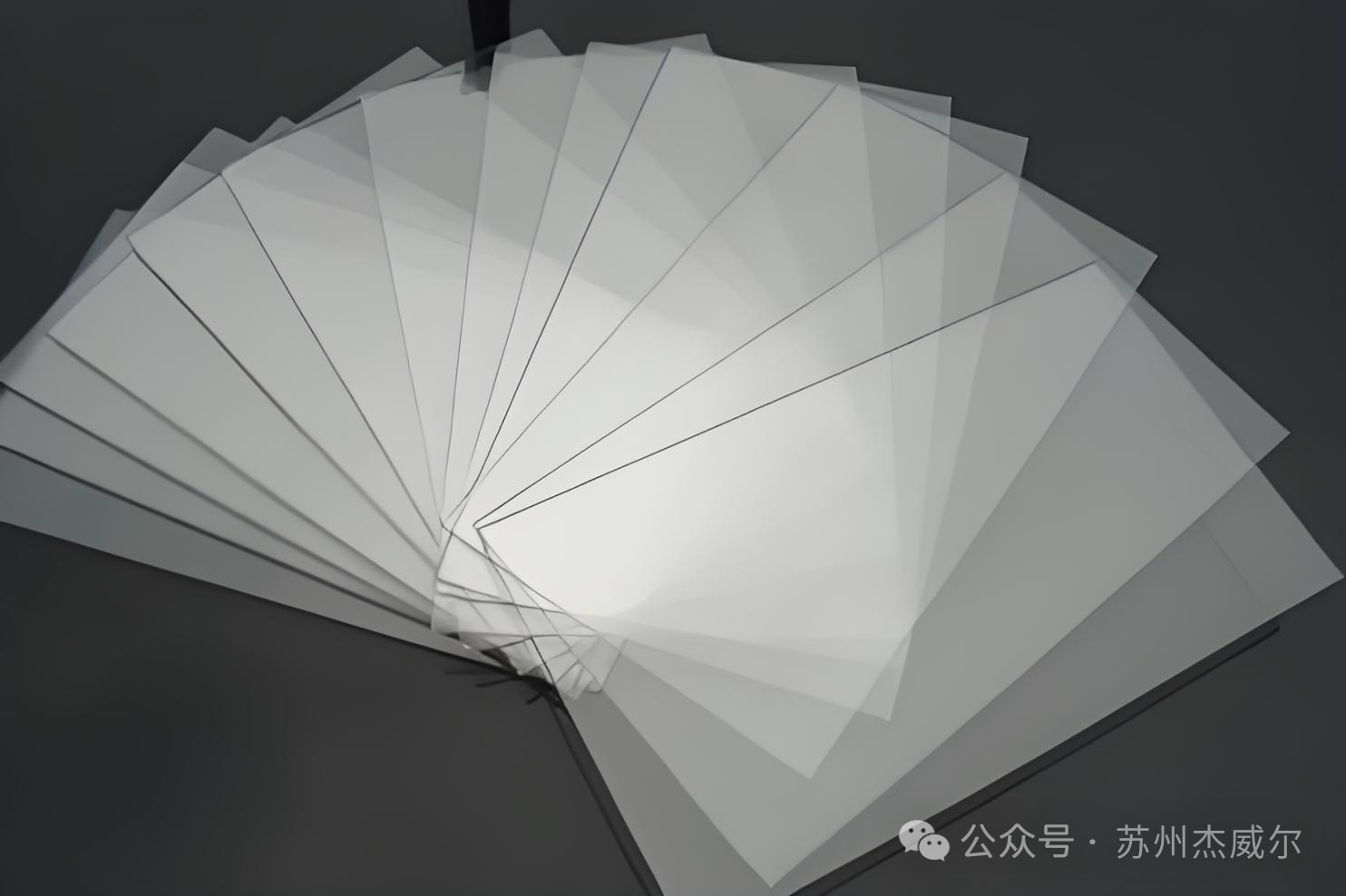

| PET | transparent sheet | 42CrMo seamless pipe | High strength, high temperature resistance, suitable for high-gloss mirror processing, and the material has high mechanical properties after heat treatment. |

PC/PMMA/GPPS | optical films, seamless tubes | 42CrMo alloy forgings | After forging, the mechanical properties and material density of the forged material can be significantly improved, and the deformation resistance of the roller is also significantly enhanced. |

| ABS/PP/PE/PVC | building materials, packaging sheets, decorative panels, foamed boards | high-quality 45# seamless steel pipe | Good processability, high cost performance, suitable for general materials |

| PP/PE | biaxially stretched thin film | stainless steel or corrosion-resistant steel | Highly corrosion resistant, preventing chloride attack. |

| Glass fiber modified plastics | engineering plastic products | high-hardness alloy steel | High wear resistance, extending service life |

For PET and PC products requiring high transparency and strict surface finish, 42CrMo rollers are the preferred choice. For ordinary products with less stringent requirements, 45# steel, which offers better cost-effectiveness, can be selected.

Behind every high-quality extrusion machine lies meticulous attention to detail. Jwell adheres to the principle of "crafting precision parts with the spirit of craftsmanship" !Follow Jwell to learn more about plastic extrusion parts!