1) Blowing pressure

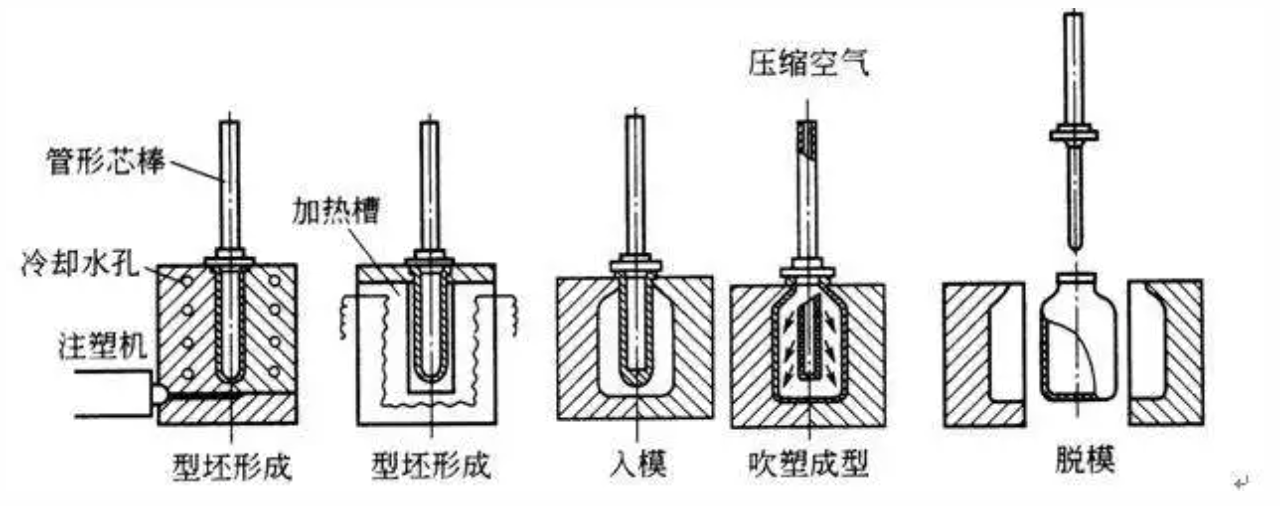

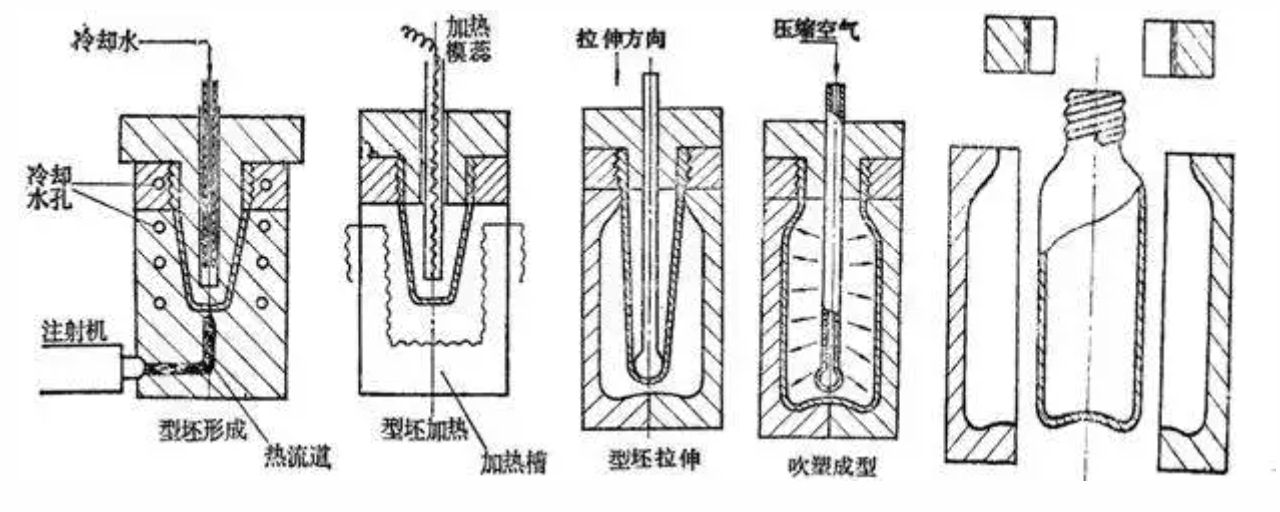

In blow molding, compressed air serves two purposes: first, it expands the tube blank to fit tightly against the mold cavity wall, forming the desired shape; second, it acts as a cooling agent.

The air pressure varies depending on the type of plastic and the temperature of the preform, and is generally controlled between 0.2 and 0.7 MPa. The most suitable pressure is one that allows the shape and pattern of the product to be clearly visible after molding.

For plastics with low viscosity and easy deformation, use lower values; for plastics with high viscosity and modulus, use higher values; for large-volume and thin-walled products, use higher pressure; for small-volume and thick-walled products, use lower pressure.

2) Inflation speed

To shorten the blowing time and achieve a more uniform thickness and better surface in the product, the inflation speed (the volume of air flowing per unit time) should be as high as possible, but not too high, otherwise it will have adverse effects on the product: First, it will create a vacuum at the air inlet, causing the parison in this part to sink in. When the parison is fully inflated, the sinking part will form a diaphragm. Second, the parison in the die part may be broken by the extremely fast airflow, resulting in scrap.

Therefore, it is necessary to increase the diameter of the blowpipe or appropriately reduce the inflation speed.

3) Blow-up ratio

The ratio of the product's dimensions to the preform's dimensions is usually called the blow-up ratio. When the preform's dimensions and weight are constant, the larger the product's dimensions, the larger the preform's blow-up ratio. The blow-up ratio is determined by the type and properties of the plastic, the shape and size of the product, and the preform's dimensions. Typically, the blow-up ratio is controlled at 2 to 4 times.

4) Mold temperature and cooling time

To ensure product quality, the mold temperature should be evenly distributed, generally maintained between 20-50 ℃ . If the mold temperature is too low, the extensibility of the plastic at the clamping point will decrease, making it difficult to inflate and causing the product to thicken in this area. This also makes molding more difficult, resulting in unclear product contours and patterns. If the mold temperature is too high, cooling time will be prolonged, extending the production cycle. The product may also deform upon demolding, and shrinkage will increase.

The mold temperature depends on the type of plastic. When the glass transition temperature of the plastic is high, a higher mold temperature can be used; conversely, the mold temperature should be reduced as much as possible.

Generally, the cooling time increases with the increase of the product wall thickness. Sometimes, in addition to cooling the mold, the molded product can also be internally cooled, that is, various cooling media (such as liquid nitrogen, carbon dioxide, etc.) are introduced into the product for direct cooling.

5) Molding cycle

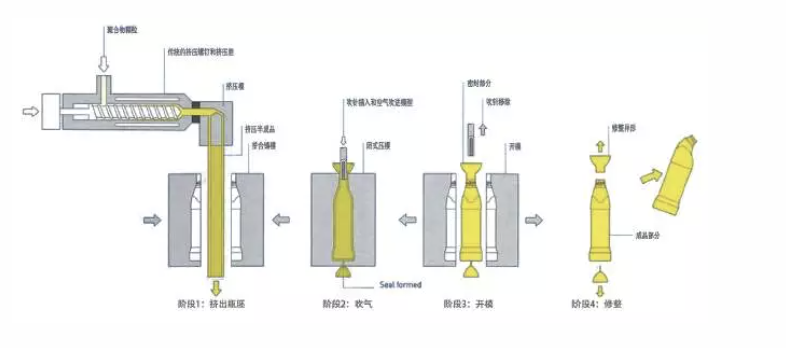

The blow molding cycle includes processes such as extruding the parison, cutting the parison, closing the mold, blowing air, cooling, venting, opening the mold, and removing the product (subsequent finishing, fitting, and packaging are separate).