A super mirror roller is a specialized roller used in industrial processes to create highly polished, mirror-like surfaces on materials.

Brief Introduction

1.Function:

Super mirror rollers are used to impart a high-gloss, reflective finish to materials such as plastic films, metal foils, and paper.

2.Design:

- Highly Polished Surface: The roller’s surface is polished to a mirror-like finish, typically achieving a surface roughness of Ra 0.01 µm or better.

- Precision Engineering: Made with precise tolerances to ensure consistent and uniform contact with the material.

3. Material:

Typically constructed from high-quality stainless steel or other durable metals, often with additional coatings or treatments to enhance hardness and wear resistance.

4.Advantage :

·The surface roughness level of the roller can be reached Ra0.005-0.01μm

·Temperature difference accuracy ≤±1℃

·Hydrogen removal process

·High-quality 45# seamless pipe, 42CrMo alloy steel forging pipe, Q345D, etc

·Enhanced roller rigidity and minimized roller surface temperature deviation through special roller structure design

5. Applications:

- Plastic Film Manufacturing: Used to produce high-gloss films for packaging and decorative purposes.

- Metal Foil Processing: Applied in the production of reflective metal foils used in electronics and decorative applications.

- Paper Coating: Utilized in the production of high-gloss, coated paper for printing and packaging.

Technical Parameters

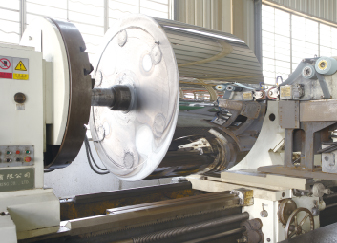

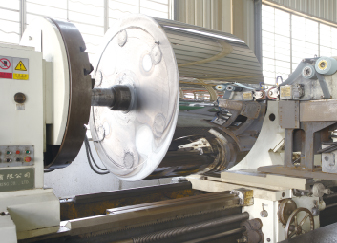

Our manufacturing capacity of roller

Max.machining length:14000mm

Max.machining diameter: ∅1600mm

Max.running speed :800 m/min

Manufacturing precision of roller:

Properalignment :≤0.005mm;

Cylindricity :≤0.005mm;

Surface roughness:Ra0.005-0.01μm

Dynamic balance correction and Static balance correction : G2.5

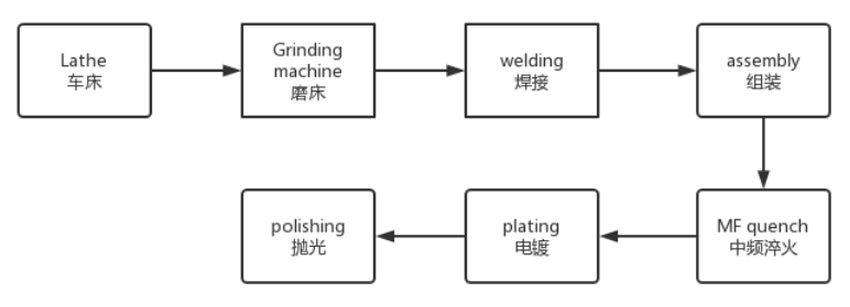

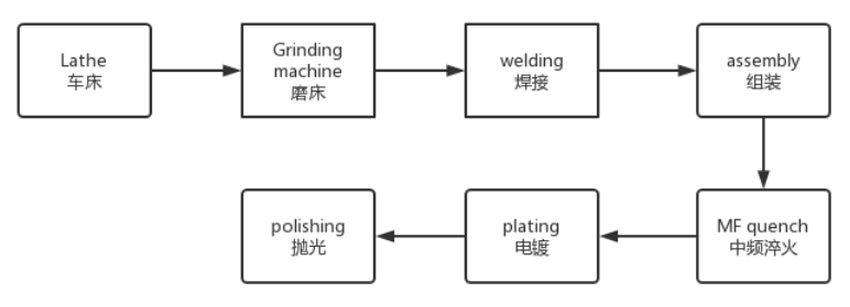

Brief Process Flow Chart