Extrusion lines are the backbone of many manufacturing processes, especially in industries such as plastic, rubber, and food production. When these systems fail, the consequences can be costly and time-consuming. One of the most critical factors in ensuring smooth operation is selecting the right screw, barrel, and roller for the specific application. These components work together to provide consistent material flow, temperature regulation, and optimal output. In this article, we will explore seven essential tips for selecting the right screw, barrel, and roller to prevent extrusion line failures and maximize production efficiency.

Understanding the Importance of the Screw, Barrel, and Roller in Extrusion

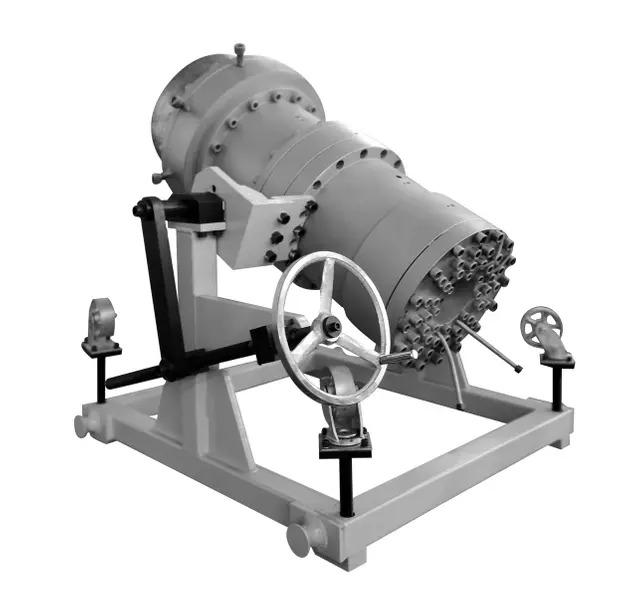

Before diving into the tips, it's crucial to understand the role of each of these components. The screw is responsible for moving the material through the extrusion system, providing both pressure and shear forces. The barrel provides the containment and the necessary heat for melting or softening the material. Lastly, the roller supports the material as it exits the extruder, helping it maintain shape and consistency.

Each of these components must be carefully matched to the material being processed, the extrusion process type, and the production environment. An improper match can lead to inefficiencies, wear and tear, product defects, and even complete system failure.

Tip 1: Choose the Right Screw Geometry

The geometry of the screw, including its pitch, diameter, and compression ratio, directly impacts the extrusion process. The pitch refers to the distance between the flights of the screw, and the diameter dictates the amount of material the screw can process at once. A compression ratio determines how much the material is compressed as it moves along the screw, which affects both the heat generation and the overall mixing process.

When selecting the screw geometry, it’s essential to consider the type of material being extruded. For example, high-viscosity materials like rubber require a screw with a larger pitch and higher compression ratio to achieve efficient material movement and melting. On the other hand, thermoplastic materials require more precise screw geometry to control the shear forces and ensure consistent product quality.

Key Considerations for Screw Geometry:

Pitch: Larger pitch screws are suitable for high-throughput applications, while smaller pitch screws provide better mixing.

Diameter: Larger diameters are ideal for processing larger volumes of material but may result in slower processing speeds.

Compression Ratio: Higher compression ratios lead to better mixing and melt quality, while lower ratios help in maintaining a more consistent flow.

Tip 2: Match the Barrel Length to the Application

The barrel length plays a critical role in the heating and melting of materials. A longer barrel allows for more time for the material to heat and melt, making it ideal for materials that require a longer processing time. A shorter barrel, however, is typically faster and more efficient for materials that need less time for melting.

Barrel length is often paired with the screw's design to ensure that the material flows smoothly through the system. It's essential to strike the right balance between barrel length and screw design to prevent uneven melting, material degradation, or other extrusion issues. A barrel that is too short may result in incomplete melting, while one that is too long can lead to overheating and material degradation.

Key Considerations for Barrel Length:

Material Type: Consider the melting point and processing time needed for the material.

Process Type: Single-stage extrusion processes may require shorter barrels, while multi-stage processes may benefit from longer barrels.

Tip 3: Select the Right Barrel Coating for Durability

Barrel coatings are crucial in preventing premature wear and tear, especially when processing abrasive materials like filled plastics or glass-reinforced composites. Coatings help reduce friction between the screw and the barrel, leading to less heat buildup and longer service life. Common coatings include chrome plating, nitriding, and ceramic coatings.

It’s also essential to consider the compatibility of the coating with the material being processed. For instance, abrasive materials can rapidly wear down barrels without appropriate coatings, leading to increased downtime and maintenance costs. In addition to protecting the barrel, coatings also help maintain consistent heat transfer, ensuring optimal extrusion performance.

Key Considerations for Barrel Coating:

Material Compatibility: Choose coatings based on the abrasiveness and chemical properties of the material.

Wear Resistance: Opt for coatings that offer increased resistance to wear and tear in high-pressure applications.

Tip 4: Evaluate Roller Surface Texture for Consistent Output

Rollers are responsible for shaping the material as it exits the extruder. The surface texture of the roller plays a significant role in the final product's quality. A roller with a smooth surface is ideal for materials that need to retain their shape without any surface defects. However, for materials that need more control or texture, a roller with a grooved or patterned surface may be more appropriate.

The roller's material—often stainless steel or ceramic—should also be chosen based on the product’s requirements. For example, high-heat materials require rollers that can withstand extreme temperatures without losing their structural integrity.

Key Considerations for Roller Surface Texture:

Smooth vs. Grooved: A smooth roller is ideal for delicate materials, while grooved rollers can help manage high-viscosity or thicker materials.

Material Type: Ensure the roller’s material is suitable for the thermal and mechanical demands of the extrusion process.

Tip 5: Consider the Impact of Temperature Control

Maintaining precise temperature control in the screw, barrel, and roller system is crucial for ensuring consistent material flow and avoiding degradation or incomplete melting. The barrel’s temperature must be carefully regulated through zones to ensure that the material reaches the desired consistency. Similarly, the screw should be designed to manage heat generation as it compresses and shears the material.

A temperature control system must be integrated into the extrusion line to monitor and adjust the heat at various points along the barrel and screw. The temperature should be adjusted based on the material being processed, as different materials have different melting and processing temperatures.

Key Considerations for Temperature Control:

Material Specifics: Ensure that the system is capable of regulating the temperature based on the material’s needs.

System Integration: Utilize automatic temperature control systems for optimal performance.

Tip 6: Regular Maintenance of the Screw, Barrel, and Roller

Routine maintenance is essential to prevent premature failures and ensure that the screw, barrel, and roller remain in good working condition. Over time, wear and tear can lead to issues such as inconsistent material flow, increased power consumption, or defective products. Scheduled maintenance, such as cleaning the barrel and checking the alignment of the screw and roller, can significantly extend the lifespan of the equipment.

Additionally, inspect seals, bearings, and other moving parts to prevent material leaks or mechanical failures. Regular maintenance can identify issues early and prevent unexpected downtime.

Key Considerations for Maintenance:

Cleaning: Keep the screw, barrel, and roller free from material buildup to ensure smooth operation.

Inspections: Perform regular checks for wear, cracks, or signs of stress that could lead to failures.

Tip 7: Analyze Material Throughput and Match to System Design

The throughput of an extrusion line refers to the amount of material processed per unit of time. Matching the screw, barrel, and roller to the required throughput is essential for preventing overloading the system and causing failures. If the system is not designed to handle the required throughput, it can lead to material backups, overheating, or breakdowns.

To optimize throughput, ensure that the components are sized appropriately to handle the maximum volume of material expected in a given time period. This also involves considering the speed of the screw, the capacity of the barrel, and the roller’s ability to handle increased volumes.

Key Considerations for Throughput:

System Sizing: Match the screw, barrel, and roller to the required throughput capacity.

Speed Control: Adjust the speed of the screw to optimize material flow and prevent system overload.

Conclusion

Selecting the right screw, barrel, and roller for an extrusion line is essential for ensuring smooth and efficient production. By understanding the role each component plays in the extrusion process and following these seven tips, manufacturers can minimize the risk of extrusion line failures. Whether it's adjusting the screw geometry, matching barrel length, or maintaining temperature control, each of these decisions can make a significant difference in the longevity and performance of the extrusion system.

FAQ

1. Why is screw geometry important in extrusion?

Screw geometry affects material movement, mixing, and heat generation. Choosing the right geometry ensures efficient material flow, proper melting, and consistent product quality.

2. How do I know the right barrel coating for my material?

Consider the abrasiveness and chemical properties of your material. Abrasive materials require more durable coatings, such as chrome or ceramic, to prevent premature wear.

3. Can a roller’s surface texture impact the extrusion process?

Yes, the roller’s surface texture affects the material’s shape and consistency as it exits the extruder. Smooth rollers are best for uniform products, while textured rollers are used for higher-viscosity materials.

4. What role does temperature control play in extrusion?

Temperature control ensures that the material melts and flows properly. Incorrect temperature can lead to poor product quality or material degradation.

5. How can I prevent extrusion line failures?

By regularly maintaining the screw, barrel, and roller, ensuring that they are properly matched to your material and throughput needs, and using the correct coatings and temperature control systems, you can significantly reduce the risk of extrusion line failures.