Introduction

When it comes to producing high-performance films, one of the most critical decisions for manufacturers is selecting the right multilayer co-extrusion line. This choice can significantly impact production efficiency, material properties, and the overall quality of the final product. Multilayer co-extrusion technology enables the production of films with enhanced barrier properties, mechanical strength, and functional characteristics, all of which are crucial for a variety of industries, including packaging, electronics, and medical applications. However, with a wide range of options available in the market, choosing the right equipment can be overwhelming.

This article will explore the key factors to consider when selecting a multilayer co-extrusion line, offering insights on the types of machines available, the materials used, and the advanced technologies that improve film quality and production efficiency. By understanding these aspects, manufacturers can make a well-informed decision that aligns with their specific production needs.

Understanding Multilayer Co-Extrusion Technology

Before diving into the selection process, it’s important to grasp the basic concept of multilayer film extrusion. This process involves extruding multiple layers of different polymer materials simultaneously to create a film that combines the benefits of each layer. Each layer contributes specific properties to the film, such as enhanced durability, heat resistance, or moisture barrier properties. This technology is commonly used in the production of packaging materials, food containers, medical films, and other specialized applications.

The multilayer co-extrusion line can have two or more extruders, each feeding a different material into a common die. The layers are fused together under high pressure, creating a uniform film with superior performance characteristics compared to monolayer films. In high-performance applications, where product functionality is key, the right multilayer co-extrusion line can make all the difference.

Key Factors to Consider When Choosing a Multilayer Co-Extrusion Line

When selecting a multilayer co-extrusion line for high-performance films, manufacturers must carefully evaluate several factors to ensure that the equipment can meet their production needs. Here are the key considerations:

A. Number of Layers and Layer Configuration

The number of layers is one of the first things to consider. Multilayer co-extrusion lines can be configured to produce films with two, three, or more layers. The specific number of layers required will depend on the properties needed in the final film. For example, a three-layer system might provide a balance of strength, barrier properties, and flexibility, while more complex configurations can deliver highly specialized functionality, such as improved gas barrier properties for food packaging.

It’s important to determine whether a standard two- or three-layer system will meet your needs or if you require a more advanced multi-layer design (up to seven or even more layers). More layers allow for more complex designs and enhanced material performance but may come at a higher initial cost.

B. Extruder Type and Configuration

The type and configuration of the extruders used in the multilayer co-extrusion line play a critical role in determining the quality and consistency of the final product. Common configurations include:

Single-screw extruders: Used for simpler material formulations and more basic applications.

Twin-screw extruders: Offer better control over material processing and are often used for more demanding applications that require higher precision and better mixing of materials.

Choosing the right extruder depends on the materials being processed. For example, high-performance films that require complex blends or additives may benefit from the versatility of twin-screw extruders. Moreover, the number of extruders needed will vary depending on how many layers are being produced.

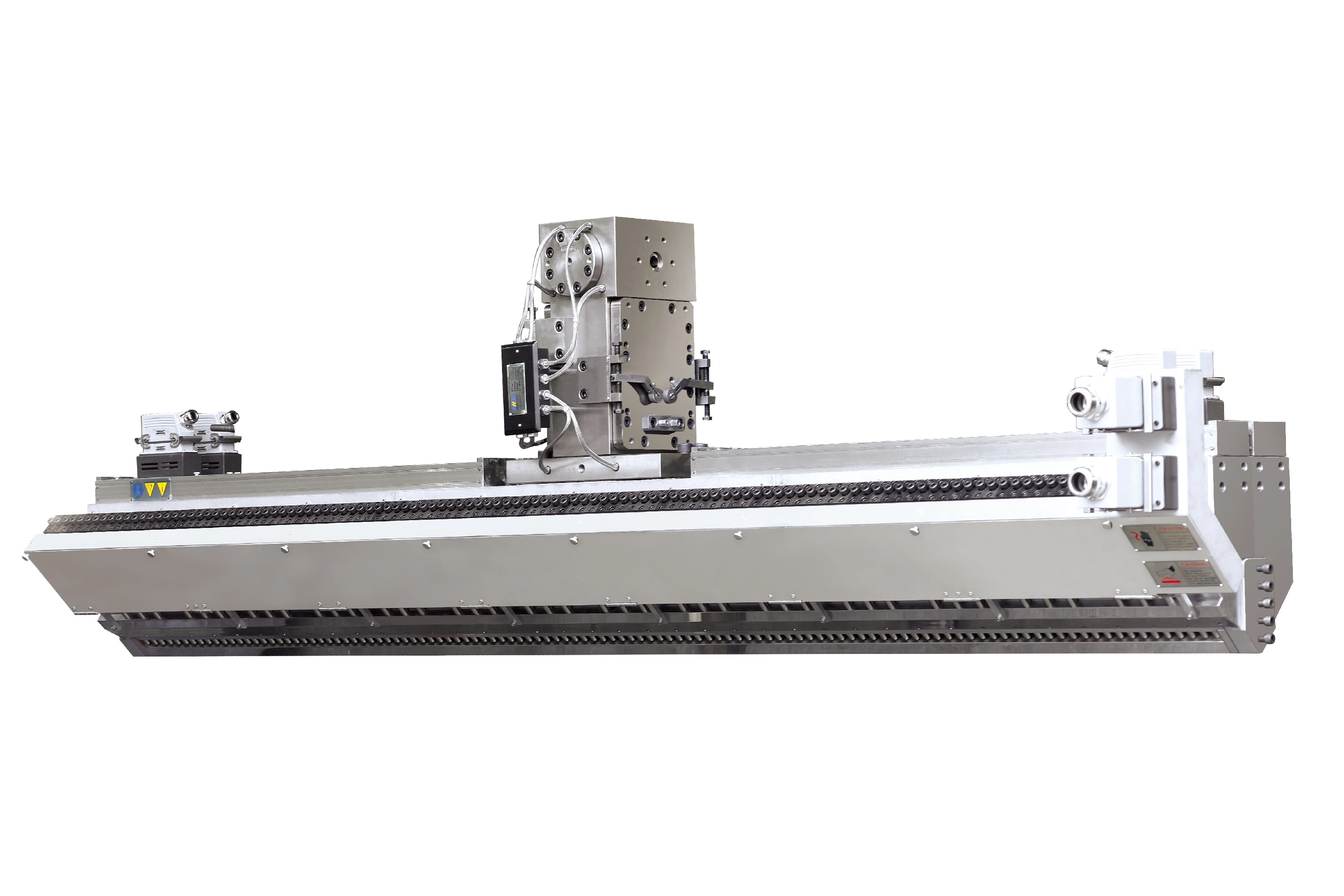

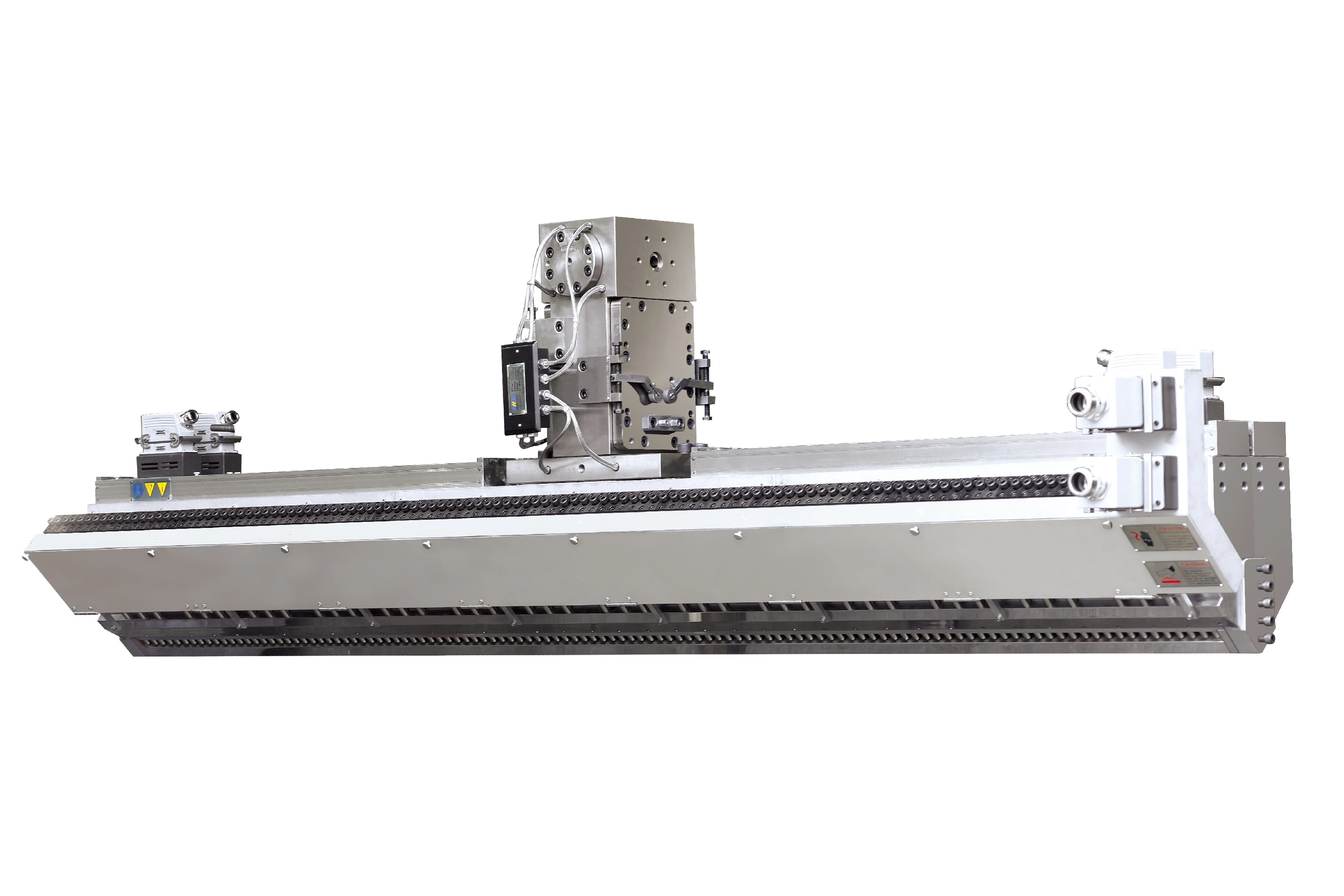

C. Die Design and Distribution System

The die is one of the most critical components in a multilayer film extrusion line, as it determines the uniformity and consistency of the final film. The distribution system within the die ensures that the layers are evenly distributed, and the film thickness is consistent throughout the production process.

For high-performance films, it's essential to choose a die that can handle precise material distribution and maintain uniformity even at high production speeds. Some dies feature advanced technologies such as spiral flow systems that improve layer bonding and minimize defects. The right die will ensure the highest-quality end product with fewer defects.

Material Compatibility and Resin Selection

The performance of the final film is heavily influenced by the materials chosen for each layer. Different materials provide unique characteristics such as barrier properties, mechanical strength, heat resistance, and printability. In high-performance applications, manufacturers may use a combination of polymers, such as polyethylene (PE), polypropylene (PP), polyamide (PA), or ethylene vinyl alcohol (EVOH).

It’s important to choose materials that are compatible with the chosen extruder configuration and die. Some resins are more challenging to process and require specialized equipment, while others may offer better processing stability. When selecting a multilayer co-extrusion line, ensure that it supports the desired resins and that the extrusion equipment is optimized for those materials.

| Material Type | Key Property | Common Applications |

| PE (Polyethylene) | Flexibility, low cost | Food packaging, consumer goods |

| PP (Polypropylene) | Chemical resistance, high strength | Medical, industrial films |

| PA (Polyamide) | High barrier, toughness | Food packaging, automotive |

| EVOH (Ethylene Vinyl Alcohol) | High barrier to gases and odors | Food packaging, medical applications |

Production Speed and Throughput

Another key factor in selecting the right multilayer co-extrusion line is the production speed and throughput. The chosen system should be capable of meeting the required production volume while maintaining high film quality. Some lines are designed for high-speed production, making them ideal for industries that require large quantities of high-performance films, such as food packaging.

High-performance films often require slower processing speeds due to the complexity of the materials and the need for precision in layer bonding. Therefore, it’s important to balance production speed with the need for quality and performance. A system with adjustable speed settings can be beneficial to accommodate different production runs.

Control Systems and Automation

Modern multilayer co-extrusion lines come equipped with advanced control systems that allow manufacturers to fine-tune every aspect of the extrusion process. Automated systems enable precise control over temperature, pressure, and extrusion speed, ensuring consistent quality throughout the production cycle.

For high-performance films, the ability to monitor and adjust the parameters in real-time is crucial for optimizing film properties and reducing defects. Look for a system that integrates well with other parts of your production line and offers flexible options for monitoring and control.

Maintenance and Support

A reliable after-sales support system and easy access to maintenance services are essential for ensuring the longevity of your multilayer co-extrusion line. Choose a manufacturer or supplier who offers robust customer support, spare parts availability, and a comprehensive warranty package.

Routine maintenance is crucial for keeping the system running at optimal performance. Select a machine with features that make it easy to clean and maintain, as downtime for maintenance can significantly impact production schedules.

Conclusion

Choosing the right multilayer co-extrusion line for high-performance films requires a detailed understanding of your specific production requirements. Key factors such as the number of layers, extruder configuration, die design, material compatibility, and production speed must all be carefully evaluated to ensure that the selected line meets the desired quality standards and production goals. With the right equipment, manufacturers can create films that offer superior barrier properties, strength, and versatility, making them ideal for a range of advanced applications.

By considering the factors discussed above, manufacturers can make an informed decision and invest in a co-extrusion line that will not only meet their current needs but also provide flexibility for future production demands.

FAQ

Q1: What is the difference between a two-layer and three-layer co-extrusion line?

A two-layer co-extrusion line produces a film with two distinct layers, each offering different material properties, such as one for strength and the other for barrier properties. A three-layer system allows for a more complex design, often combining three materials with distinct functions, such as a core layer with two outer barrier layers.

Q2: Can multilayer co-extrusion lines process biodegradable materials?

Yes, many modern multilayer co-extrusion lines are capable of processing biodegradable polymers such as PLA (polylactic acid), offering manufacturers the flexibility to produce environmentally-friendly films.

Q3: How does the extruder configuration impact the quality of the film?

The extruder configuration affects the film's consistency, strength, and processing stability. A twin-screw extruder, for example, can offer better mixing and more precise control over the material blend compared to a single-screw extruder.

Q4: What are some common applications of high-performance multilayer films?

High-performance multilayer films are used in a variety of industries, including food packaging, medical applications, electronics, and automotive industries, where advanced barrier properties, strength, and durability are essential.