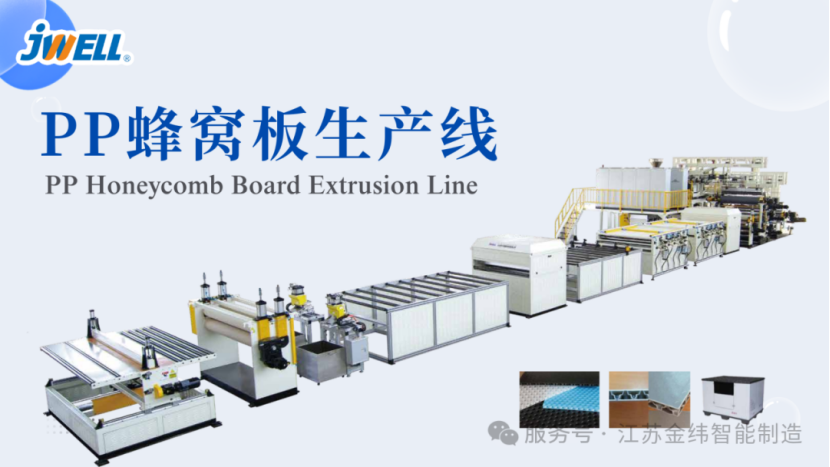

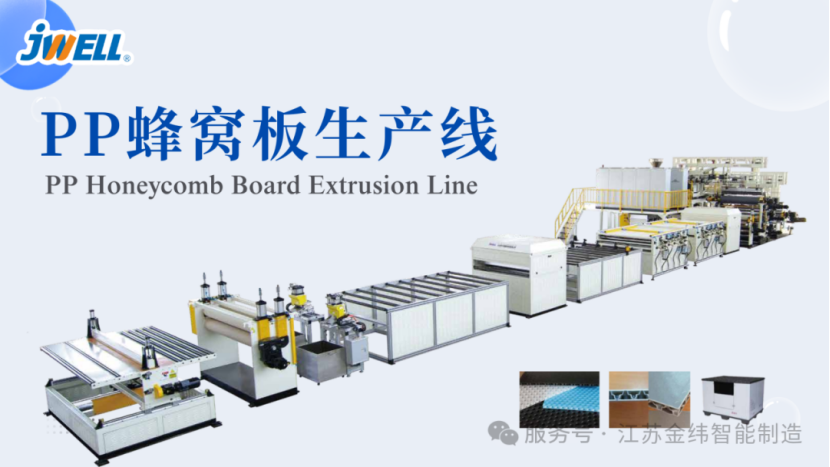

Jwell PP honeycomb board Extrusion Machine Line

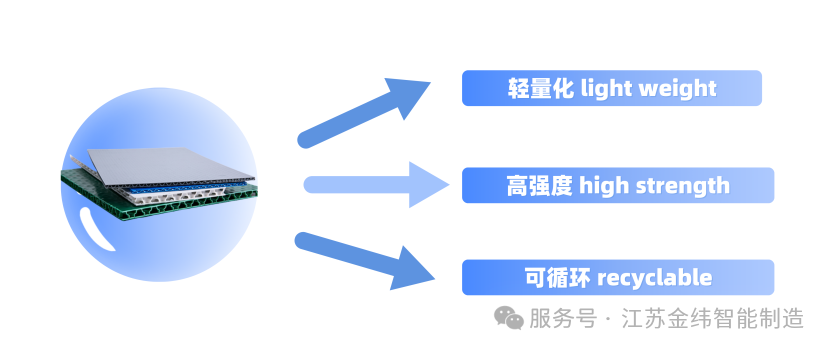

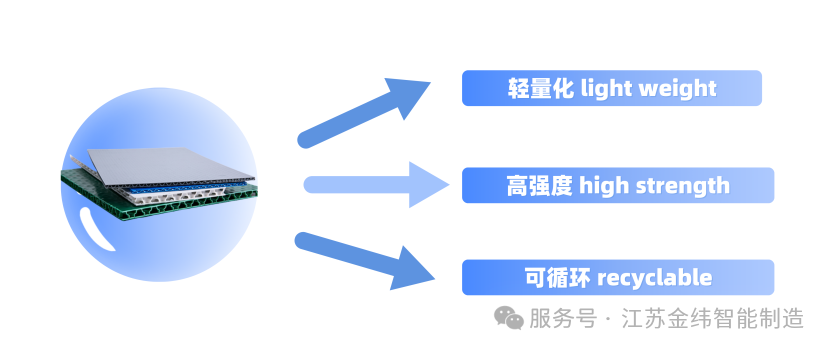

PP honeycomb board, often also known as PP honeycomb board or plastic honeycomb board, are lightweight, high-strength board made from polypropylene as the main raw material, mimicking the structure of a honeycomb.

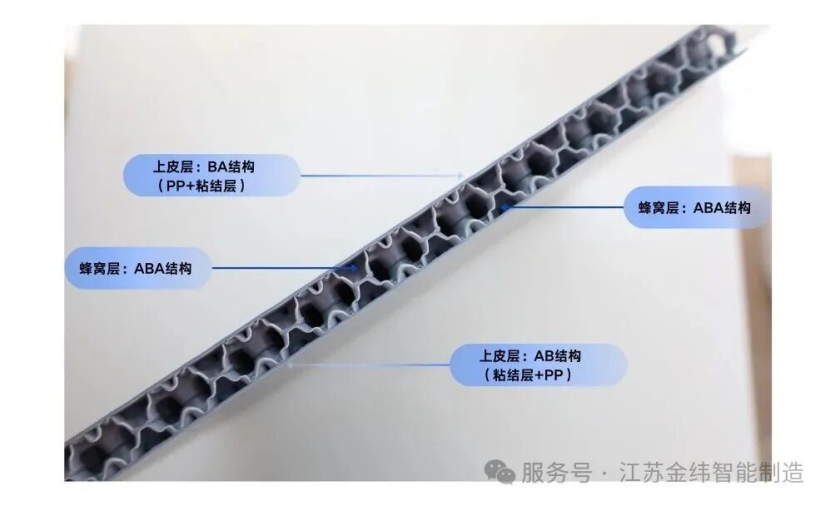

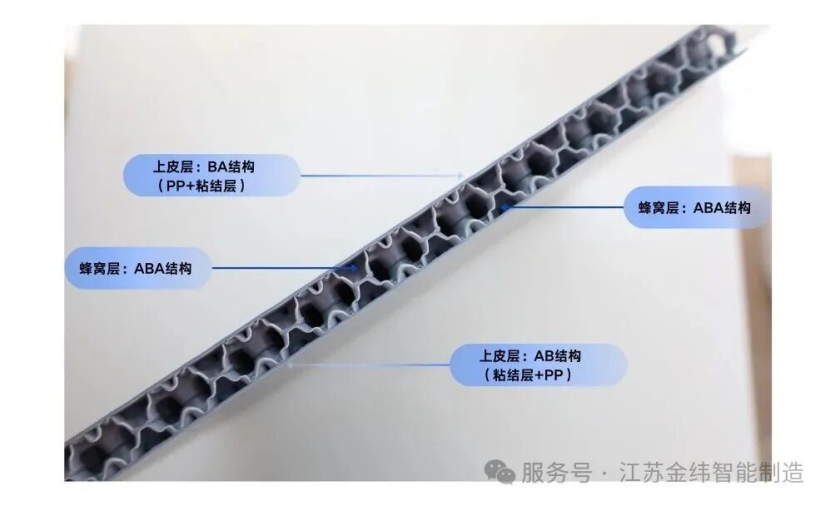

Honeycomb core layer: The core part, a honeycomb hexagonal lattice structure of holes made of PP. This structure is the key to the lightness and strength of the material.

Flat surface layer: top and bottom, with PP flat sheets laminated to the honeycomb core by hot-melt technology to form a flat surface.

Market competition is becoming increasingly fierce, and high efficiency and environmental protection have become key considerations. With the bionic honeycomb structure, honeycomb panels achieve ultra-high strength with extremely light weight, which has significant advantages in reducing transport costs and improving material utilisation.

At the same time, its recyclable and low energy consumption characteristics perfectly fit the trend of green development, becoming the material of choice for cost reduction, efficiency and sustainable development in the construction, packaging, transport and other industries.

The wise man knows that quality products cannot be separated from the support of advanced equipment. Today, we would like to share with you Jwell PP honeycomb board production line.

PP honeycomb panel composite production line adopts PLC centralised control, which sequentially completes automatic loading, three-layer co-extrusion (surface layer, honeycomb layer, bottom layer), heating composite, calendering and moulding. Subsequently, the production is completed by traction, tempering stress relief, natural cooling, trimming and width setting, then cutting through fixed length, and finally automatic stacking with optional hydraulic stacker.

Jwell PP honeycomb board production line, known for its high output and high speed, can produce up to 800 - 2000kg per hour, helping enterprises to improve production efficiency.

Our equipment produces honeycomb board products with flat surface, high composite strength, stable and reliable quality, which are widely favoured by the market.

Perfect core structure, robust interface lamination, stable high-speed production - these are the core elements that make high-end PP honeycomb boards.

According to the width of the products and output requirements, single-screw or twin-screw extruder can be selected. The extruder is equipped with gear pumps and pressure closed-loop control through PLC, thus ensuring stable pressure and uniform discharge after the melt enters the die cavity to ensure consistent thickness of the sheet.

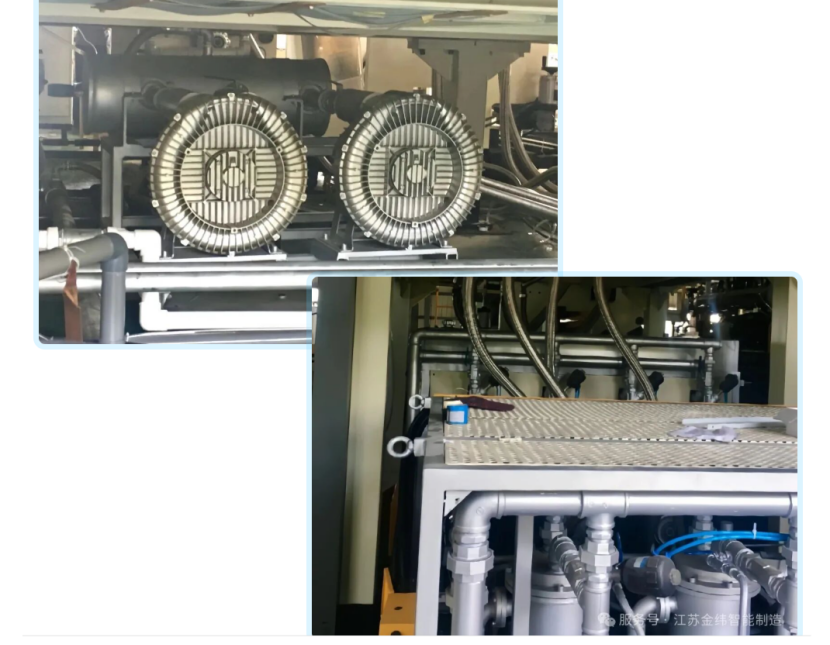

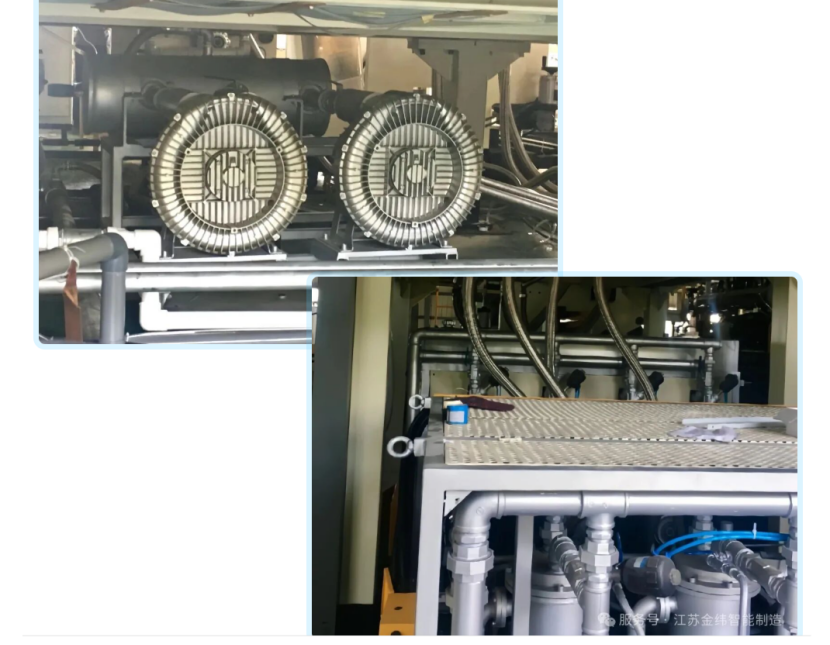

Roller temperature control and negative pressure system for honeycomb rollers. Each moulding roller is equipped with an independent temperature control system, which automatically adjusts the PID of the medium entering the roller, and can achieve the surface temperature of the roller at a constant temperature.

Compared with the commonly used equipment in China, our company takes the lead in adopting the advanced method of moulding three layers of products independently and then forming them as a whole through thermal composite moulding in the sheet moulding process.

This process not only realises the precise regulation of the thickness of the upper and lower surface layers, ensuring high flatness of the composite plate surface, but also accurately controls the overall weight, significantly improving the appearance quality and processing performance of the final plate.

Jwell Machinery was established in 1997, as one of the largest professional manufacturers of extrusion equipment in China. Through continuous and steady development, our company has built up a globalised production layout, with 14 modern production bases in various places in China such as Jiading district of Shanghai, Zhoushan City and Haining of Zhejiang Province, Taicang City and Liyang City of Jiangsu Province, Dongguan City and Foshan City of Guangdong Province, Chuzhou City of Anhui Province, as well as in Thailand, Spain and Germany.

Jwell Machinery independently develops and processes screws, barrels, moulds, rollers, screen changers, etc., and strictly controls the quality of key components.Comparable to the quality of top German extruders at a reasonable and affordable price.

With offices in Vietnam, Turkey, Thailand, Brazil, and Canada, Jwell has more than 800 engineers specialising in their fields to serve customers worldwide.

Jwell provides regular spare parts delivery service within 24 hours, professional maintenance advice and lifelong equipment maintenance service.