High-speed Thin Film Coating Die Head: Boosting High-quality Development of The New Energy Industry

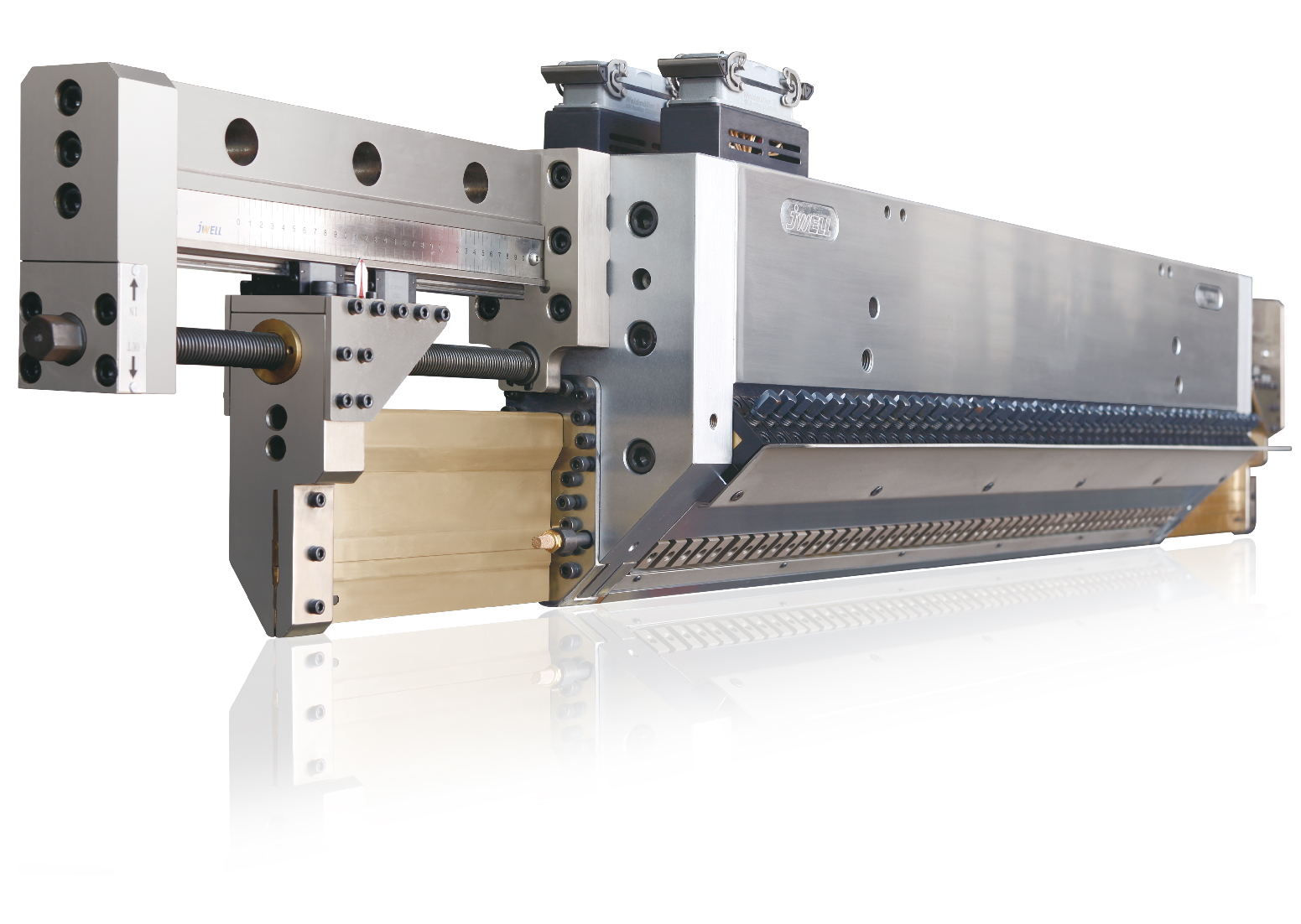

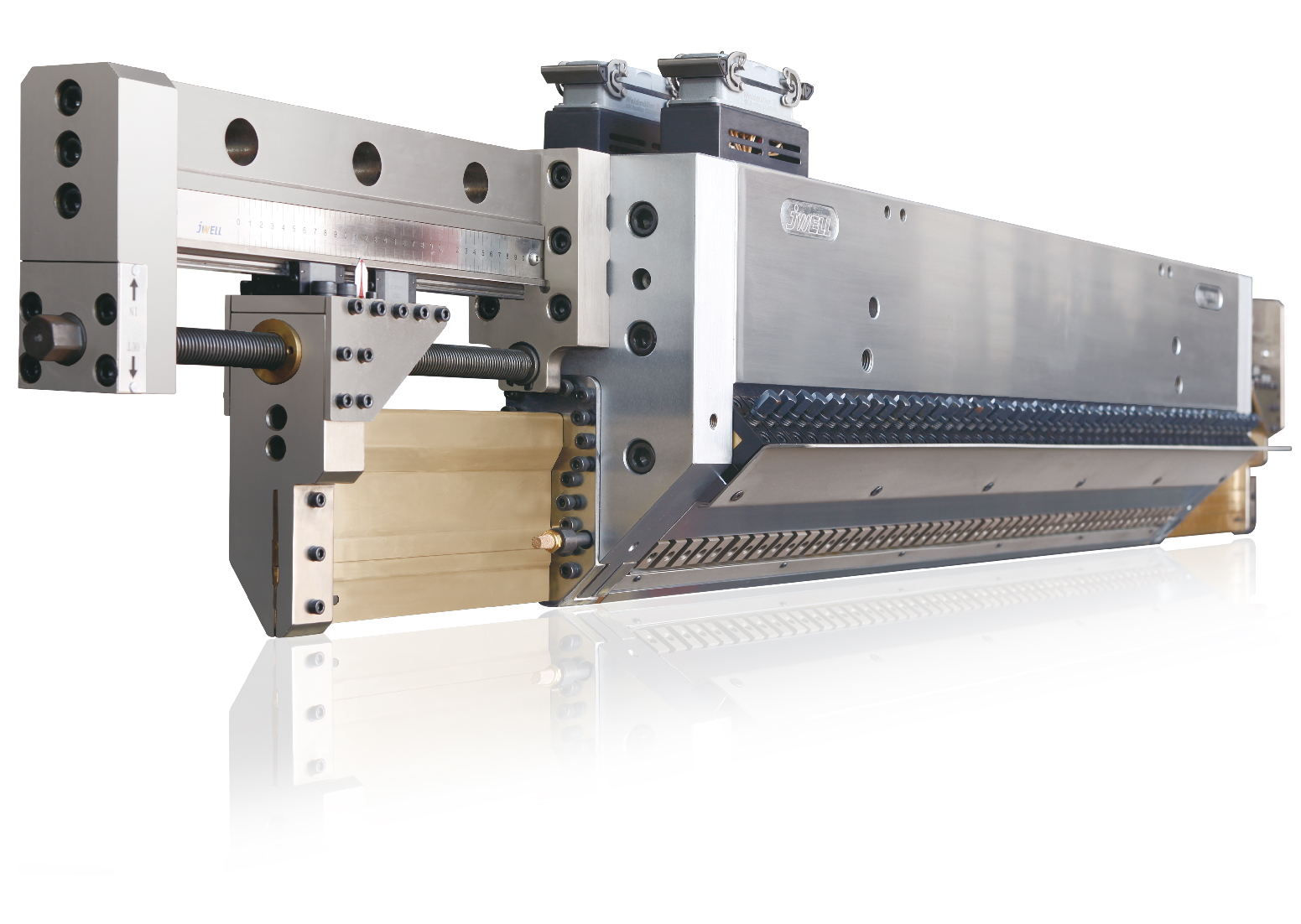

One. The high-speed thin-film coating die head, commonly referred to as the "slot-die coating head," serves as the core "precision brush" in modern advanced manufacturing. It consistently and accurately "deposits" functional liquids (such as battery slurries, optical adhesives, etc.) onto rapidly moving substrates, forming an ultrathin yet critical functional coating layer.

To fulfill this precision mission, the die of Suzhou JWell itself must be exceptionally robust. In terms of material selection, it is typically constructed from specialty stainless steel or advanced functional materials—characterized by high hardness, corrosion resistance, and a low coefficient of thermal expansion. This ensures structural stability and prevents deformation in high-speed, high-pressure production environments. Equally critical is the surface treatment of its internal flow channels and lip area, which undergoes mirror-level fine polishing to achieve extremely low surface roughness. This not only maximizes smoothness and reduces fluid resistance but, more importantly, prevents any minor slurry residue or buildup, eliminating potential defects at their source during the production process.

It is precisely through such intrinsic precision engineering and reliability that high-speed coating dies are able to drive the development of multiple cutting-edge industries:

Core Application: The New Energy Battery Field

It serves as the "heart" in manufacturing lithium battery cathodes and anodes. The uniformity of the coating is directly linked to the battery's energy density, safety, and lifespan.

High-End Application: Display and Semiconductor Sectors

From the light-emitting layers of flexible displays to critical coatings in chip fabrication, its precision defines the performance ceiling of electronic products.

Fundamental Application: Special Functional Films

It imparts key barrier, optical, or adhesive properties to materials like solar backsheets, high-end packaging films, and specialty tapes.

Future-Focused Application: Advanced Material Exploration

It also acts as an indispensable bridge for next-generation technologies—such as fuel cells and perovskite solar cells—transitioning from the lab to mass production.

Tow. As the new energy industry assumes a pivotal role in the new era, both production efficiency and product quality place equally high demands on the precision and stability of related equipment components. Any imbalance between these factors could hinder the industry's leap forward. Amid this race to reduce costs, enhance efficiency, and improve quality, a critical upstream segment of the industrial chain is increasingly demonstrating its value—high-speed thin-film coating. At the heart of this process lies the high-speed thin-film coating die. Through its meticulous control down to the slightest detail, it fundamentally drives the high-quality advancement of the new energy industry.

1 Precision Tolerance: The Accuracy Benchmark in Battery Manufacturing

Within the lithium battery manufacturing system, the uniformity of electrode coating is not merely a process metric but a critical determinant of battery performance. Conventional coating processes often struggle to maintain uniformity during high-speed production, where minor thickness variations or subtle streaks—imperceptible to the eye—can become hidden flaws that compromise battery consistency. Ultimately, these imperfections manifest as inconsistencies in electric vehicle range and introduce uncertainties in battery pack safety.

Suzhou JWell’s high-speed slot-die coating head, designed through years of accumulated industry experience, fundamentally addresses this industry challenge. Its precisely engineered flow channel design, based on complex fluid dynamics calculations, enables accurate and uniform deposition of slurry onto ultra-wide substrates. Combined with the thermal stability of specialized alloy materials, the high-precision lip gap control technology ensures precise and controllable management of every detail during the coating process.

This advancement in die equipment enables the lateral deviation of coating thickness to be consistently controlled within an extremely narrow range, reaching industry-leading levels in some high-end applications. This means that throughout the production of electrode sheets spanning thousands of meters, every inch of the coating maintains exceptional uniformity. From the head to the tail of the cell and from the center to the edges, the highly even distribution of active materials directly translates into stable energy density output, significantly extended cycle life, and comprehensively enhanced safety margins for the battery. Such a robust foundation of quality, established at the very source, provides solid material assurance for the reliable performance of new energy vehicles.

2 Cost Reduction and Efficiency Enhancement: Efficiency and Industrial Scale

The competition in the new energy industry has entered a critical phase of cost control. High-speed coating dies demonstrate robust capabilities in breaking through these constraints, driving industry-wide cost reduction and efficiency improvement through three innovative pathways.

In terms of production capacity expansion, the design of the new generation of coating dies has pushed the coating speed to new heights, reaching hundreds of meters per minute. This breakthrough in speed not only signifies a substantial increase in single-line production capacity but, more importantly, significantly reduces the unit manufacturing cost through scaling effects. According to industry estimates, for every 100 meters per minute increase in coating speed, the annual production capacity of a single production line can increase by approximately 1.5 GWh. This holds strategic significance for addressing the explosive growth in market demand.

Material utilization represents another critical dimension of cost control. Through precise flow management and intelligent edge-cut technology, modern coating dies can apply the slurry almost entirely within the effective area, reducing the unavoidable "edge-trim" waste typical of conventional processes to an extremely low level. Given the cost of hundreds of thousands of yuan per ton for cathode materials such as high-nickel ternary and lithium iron manganese phosphate, every 1% reduction in slurry waste translates to tens of millions of yuan in direct cost savings for a battery factory with an annual capacity of 10 GWh. This refined material control capability is reshaping the entire industry's cost structure.

The flexible production capability reflects the intelligent advancement of die technology. With modular design integrated with rapid changeover systems, the same production line can switch between manufacturing electrode sheets of different specifications and material systems in an exceptionally short time. This agile production model not only reduces equipment investment costs but also enables battery manufacturers to swiftly adapt to diverse market demands, thereby gaining a competitive edge in the fiercely contested industry landscape.

3 Frontier Technology Exploration: Paving the Way for Next-Generation Battery Advancements

As cutting-edge technologies such as solid-state batteries and silicon-carbon anodes gradually transition from the laboratory to industrialization, they present unprecedented challenges to coating processes. High-speed coating die technology is demonstrating its pivotal platform value in these domains.

In the field of solid-state batteries, unlike traditional liquid electrolytes, solid electrolyte layers require thinner, more uniform, and defect-free coating processes. Through specialized flow channel design and temperature control systems, new-generation coating dies enable precise deposition of solid electrolyte slurries, clearing the path for the mass production of solid-state batteries. Similarly, in silicon anode applications, given the volumetric expansion of up to 300% during charge-discharge cycles, exceptionally uniform coatings are essential to buffer stress distribution. This imposes near-rigorous demands on coating precision.

In response to next-generation battery materials with high solid content and viscosity, die technology continues to innovate. By optimizing internal flow channel curves and adopting specialized surface treatment techniques, new-generation dies are capable of processing ultra-high-viscosity, high-solid-content slurries while maintaining exceptional coating quality. This breakthrough in material adaptability opens new possibilities for further enhancing battery energy density.

The deep integration of digitalization and intelligence is redefining the precision boundaries of coating processes. Equipped with real-time temperature control, automatic lip micro-adjustment (ARM), and intelligent closed-loop feedback systems, "smart dies" can sense and compensate for process fluctuations in real-time. Leveraging big data analytics and machine learning algorithms, the coating process is evolving from a craft reliant on master technicians' experience into a data-driven precision science. This technological advancement not only enhances product consistency but also lays the hardware foundation for achieving "lights-out factory"-level intelligent production.

4 New Energy Industry Collaboration: Building a New Ecosystem for High-Quality Manufacturing

The advancement of high-speed coating dies is not merely a breakthrough at a single technological node but a reflection of collaborative innovation across the entire industrial chain. From the development of specialty steels and the enhancement of precision machining technologies to the progress in fluid simulation software, innovation at every stage is driving the iterative upgrading of die technology.

This synergistic effect is generating a powerful technology spillover. The successful application of coating dies in the new energy sector is rapidly extending to other advanced manufacturing fields. In perovskite solar cells, coating die technology provides critical process support for the industrialization of this low-cost, high-efficiency photovoltaic innovation. For hydrogen fuel cells, the precision coating of proton exchange membranes directly impacts battery performance and lifespan. In flexible electronics, the accuracy of functional film coating determines the reliability of the final product.

Three .A Critical Pivot Point for the New Energy Industry's Transition to High-Quality Development

As the new energy industry evolves from "whether it exists" to "how well and strongly it performs" in this new phase of development, core process equipment such as high-speed thin-film coating dies is increasingly playing a foundational role. It is not merely a component on the production line but an epitome of technological progress across the entire industry and a crucial pivot point for high-quality advancement.

Investing in and developing more advanced high-speed coating die technology means focusing on the future competitiveness of the new energy industry. By enabling more precise manufacturing processes, more efficient production methods, and superior product quality, it drives the entire new energy sector toward higher-value segments. This development model, driven by core technology, not only enhances the global competitiveness of China's new energy industry but also contributes Chinese wisdom and strength to global energy transition and sustainable development.