In the world of polymer processing and plastic manufacturing, single screw extruders are among the most widely used machines. These versatile systems offer a simple yet powerful method for converting raw plastic materials into various finished and semi-finished products. From plastic tubing and sheets to films and filaments, the single screw extruder plays a vital role in shaping our modern material landscape.

But what makes single screw extruders so integral to the industry is not just their efficient design—it's also their compatibility with a wide range of plastic materials. This article explores the most common types of polymers processed with single screw extruders, how these materials behave during extrusion, and where the resulting products are used across industries. We'll also touch on how manufacturers like Jwell support the continued advancement of extrusion technology.

The Working Principle of Single Screw Extruders

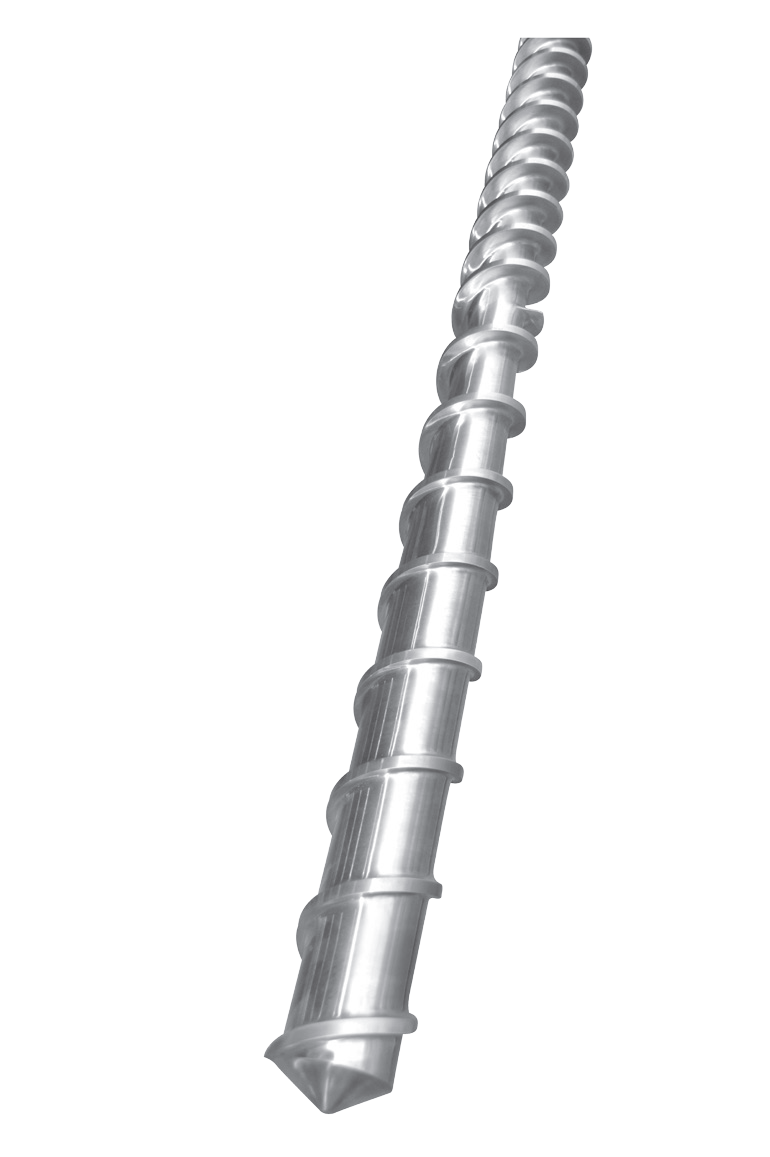

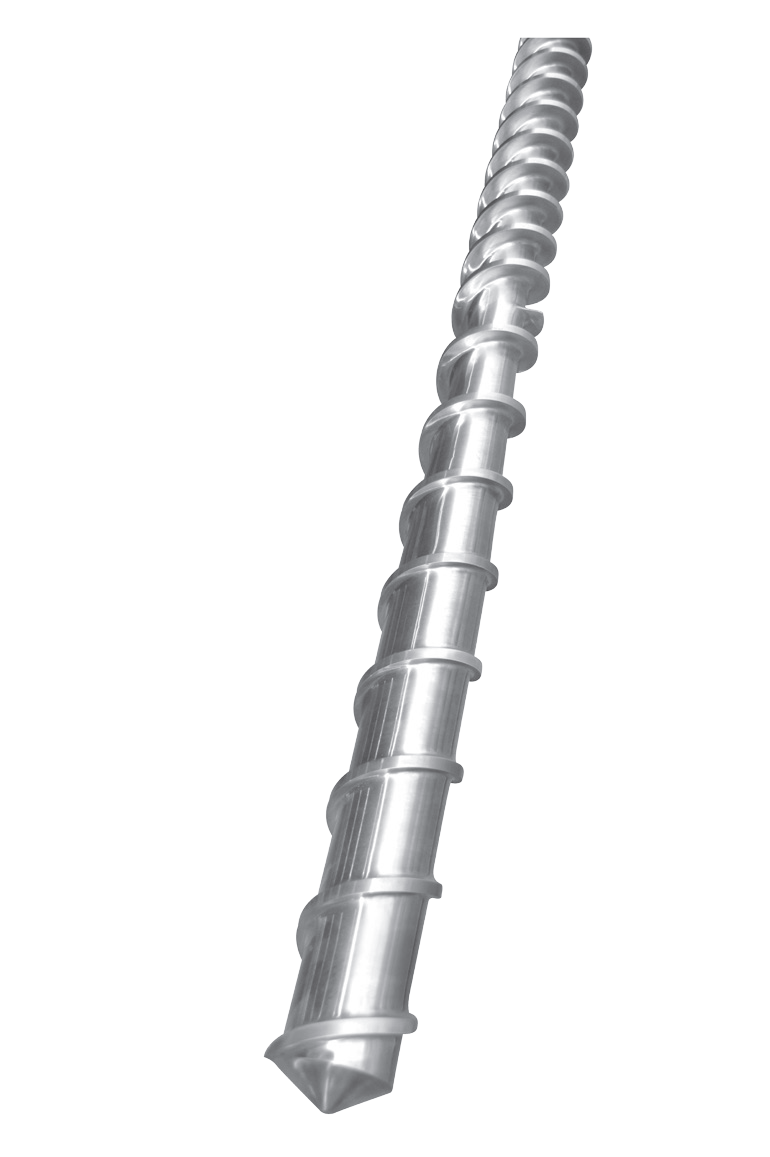

To fully appreciate the relationship between polymers and single screw extrusion, it helps to understand the basic operation of the machine. A single screw extruder consists of four main components: the feed hopper, the barrel, the rotating screw inside the barrel, and the die. Plastic materials are fed into the hopper in the form of pellets or granules. As the screw rotates, it conveys the material forward, simultaneously applying heat and pressure. The plastic melts, mixes, and is forced through a die at the end of the barrel, taking on a new shape.

This process is continuous, making it highly efficient for mass production. The simplicity of the design makes it ideal for handling a broad spectrum of thermoplastics.

Key Material Characteristics for Extrusion

The suitability of a polymer for extrusion depends on several physical and thermal properties. These include:

Melt flow index (MFI): A measure of how easily the material flows when melted.

Thermal stability: Determines whether the polymer can withstand the heat applied during extrusion.

Viscosity and elasticity: These influence how the material behaves under pressure and how it fills the die.

Additive compatibility: Some applications require mixing with colorants, UV stabilizers, or reinforcements.

Now, let’s explore some of the most widely used polymers in single screw extrusion.

1. Polyethylene (PE)

Polyethylene is one of the most commonly processed plastics using single screw extruders. There are several grades, including:

Low-Density Polyethylene (LDPE): Known for its flexibility and toughness.

High-Density Polyethylene (HDPE): Offers rigidity and strength.

Linear Low-Density Polyethylene (LLDPE): Combines flexibility with tensile strength.

Applications:

Packaging films and bags (LDPE, LLDPE)

Pipes and tubing for water and gas (HDPE)

Insulation for electrical wires

Agricultural films

PE’s excellent processability, low cost, and good chemical resistance make it a top choice for continuous extrusion.

2. Polypropylene (PP)

Polypropylene is another thermoplastic favored for its light weight, chemical resistance, and relative strength. PP melts at a slightly higher temperature than PE, and it exhibits excellent flow behavior in a single screw extruder.

Applications:

Because PP can be easily modified and blended, it’s widely used in both rigid and flexible applications.

3. Polyvinyl Chloride (PVC)

PVC is a unique case in single screw extrusion due to its thermal sensitivity. It requires tighter control over temperature to avoid degradation. However, with proper formulation and careful process management, both rigid and flexible forms of PVC can be extruded successfully.

Applications:

Pipes and fittings for plumbing and sewage systems

Electrical cable insulation

Window frames and door profiles

Medical tubing

PVC’s ability to resist corrosion, chemicals, and fire makes it an ideal material for building and infrastructure.

4. Polystyrene (PS)

Polystyrene is known for its ease of processing and clarity. Though it is brittle compared to other thermoplastics, it finds use in a variety of packaging and consumer goods.

Applications:

Disposable cups, trays, and cutlery

CD/DVD cases

Housings for electronic products

Foam boards for insulation (when processed as expanded polystyrene)

PS extrudes at a moderate temperature and provides a smooth, glossy surface finish.

5. Acrylonitrile Butadiene Styrene (ABS)

ABS is a tough, impact-resistant plastic that combines three monomers to offer superior mechanical properties. It is often extruded to create sheets or profiles used in demanding applications.

Applications:

Though more complex than simpler polymers, ABS offers a balance of strength, flexibility, and surface quality, making it suitable for many extruded products.

6. Polycarbonate (PC)

Polycarbonate is a high-performance plastic known for its strength and clarity. It requires more heat and energy during extrusion, but the results are exceptional in terms of durability and transparency.

Applications:

Transparent panels and glazing

Safety shields and machine guards

Lighting diffusers

Automotive headlamp lenses

Despite its processing challenges, PC is often used where safety and appearance are top priorities.

7. Thermoplastic Elastomers (TPEs)

TPEs behave like rubber but can be processed like thermoplastics. They are increasingly used in applications that require both flexibility and ease of manufacturing.

Applications:

TPEs are especially well-suited for co-extrusion with rigid plastics to produce dual-material parts.

Tailoring Extrusion to Material Needs

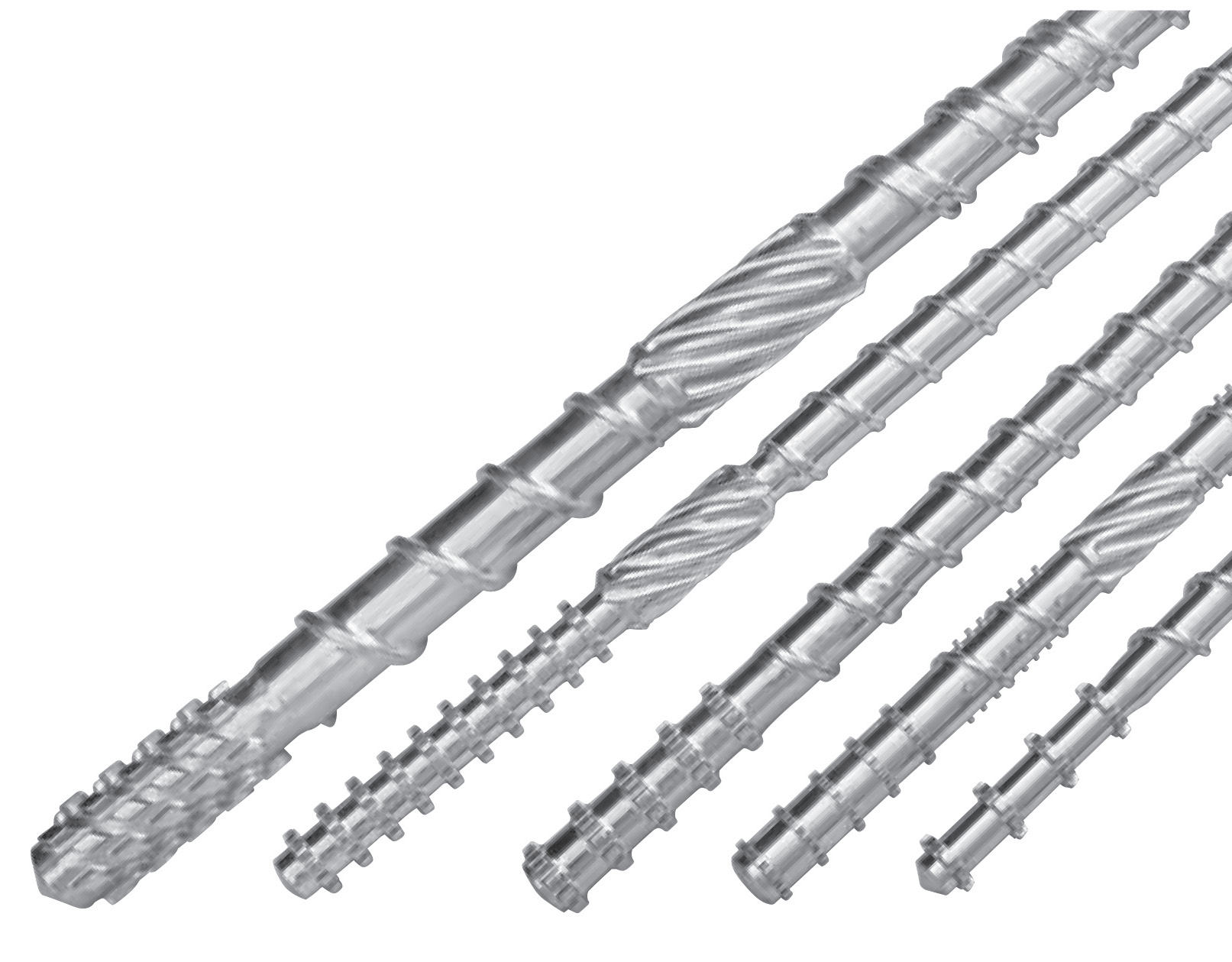

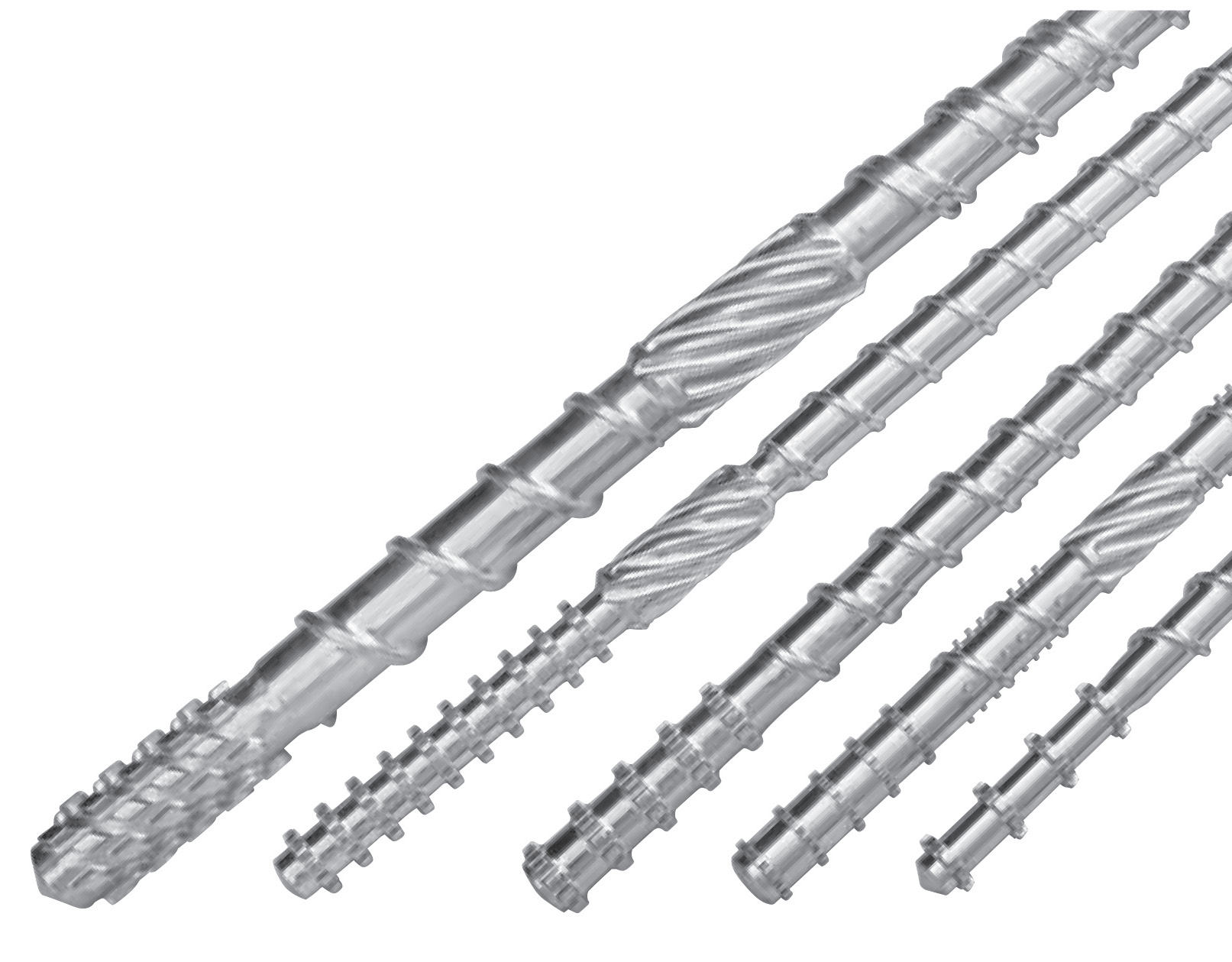

While the single screw extruder is a general-purpose machine, its configuration can be fine-tuned to the polymer being processed. Factors like screw diameter, L/D ratio (length-to-diameter), screw profile, and heating zones must be adjusted to suit the thermal and flow characteristics of the material.

For example:

PE and PP: Require standard screw geometries and moderate temperatures.

PVC: Needs a screw with mixing zones and tight temperature control.

PC and ABS: Benefit from screws with deep feed zones and high shear capacity.

Moreover, the addition of vacuum vents or side feeders may be necessary when processing filled or moisture-sensitive compounds.

Downstream Equipment and Product Variability

Once the material exits the die, it passes through downstream equipment such as cooling tanks, calibrators, or take-up rollers. The cooling and sizing process is crucial in determining the dimensional stability and surface finish of the extruded product.

Different die designs also allow for incredible versatility:

Flat dies for sheets and films

Annular dies for pipes and tubing

Profile dies for window frames, moldings, or cable trays

This ability to shape a wide range of materials into various forms underlines the single screw extruder’s unmatched value in manufacturing.

Choosing the Right Material for Your Application

When selecting a polymer for extrusion, manufacturers must consider:

Application environment: Will the product face heat, UV exposure, chemicals, or mechanical stress?

Regulatory requirements: Food-safe, medical-grade, or flame-retardant materials may be needed.

Aesthetics and finishing: Transparency, gloss, or texture might be essential.

Cost-performance balance: Budget constraints must align with product quality expectations.

By matching the polymer’s properties to the application’s demands, manufacturers can ensure the best balance of performance, reliability, and cost-efficiency.

The Role of Equipment Manufacturers like Jwell

As demand for higher-quality and more complex plastic products grows, manufacturers need extrusion equipment that is reliable, customizable, and technologically advanced. This is where trusted suppliers like Jwell play a pivotal role.

Jwell has developed a wide range of single screw extruders capable of processing various thermoplastics efficiently. Their focus on innovation, automation, and energy-saving designs helps manufacturers meet evolving production goals with ease.

From equipment consultation to after-sales service, Jwell offers the technical support and custom solutions necessary to ensure extrusion success across multiple industries.

Conclusion

Single screw extruders are a cornerstone of modern plastics manufacturing, offering unmatched versatility for processing a wide range of materials. From common polymers like PE and PP to high-performance options like PC and ABS, each material brings unique characteristics that influence both the extrusion process and the final product’s function.

Understanding how these materials behave and where they are best used allows manufacturers to optimize production lines, improve product quality, and remain competitive in a fast-paced market.

As the industry continues to evolve, innovations in screw design, material science, and automation will expand the capabilities of single screw extruders even further. With experienced partners like Jwell, companies can leverage the full potential of their extrusion systems and confidently meet the challenges of today’s demanding applications.